EUBP STATEMENT on the EU policy framework on biobased, biodegradable and compostable plastics

Comments on biobased plastics

Key advantages of using biomass:

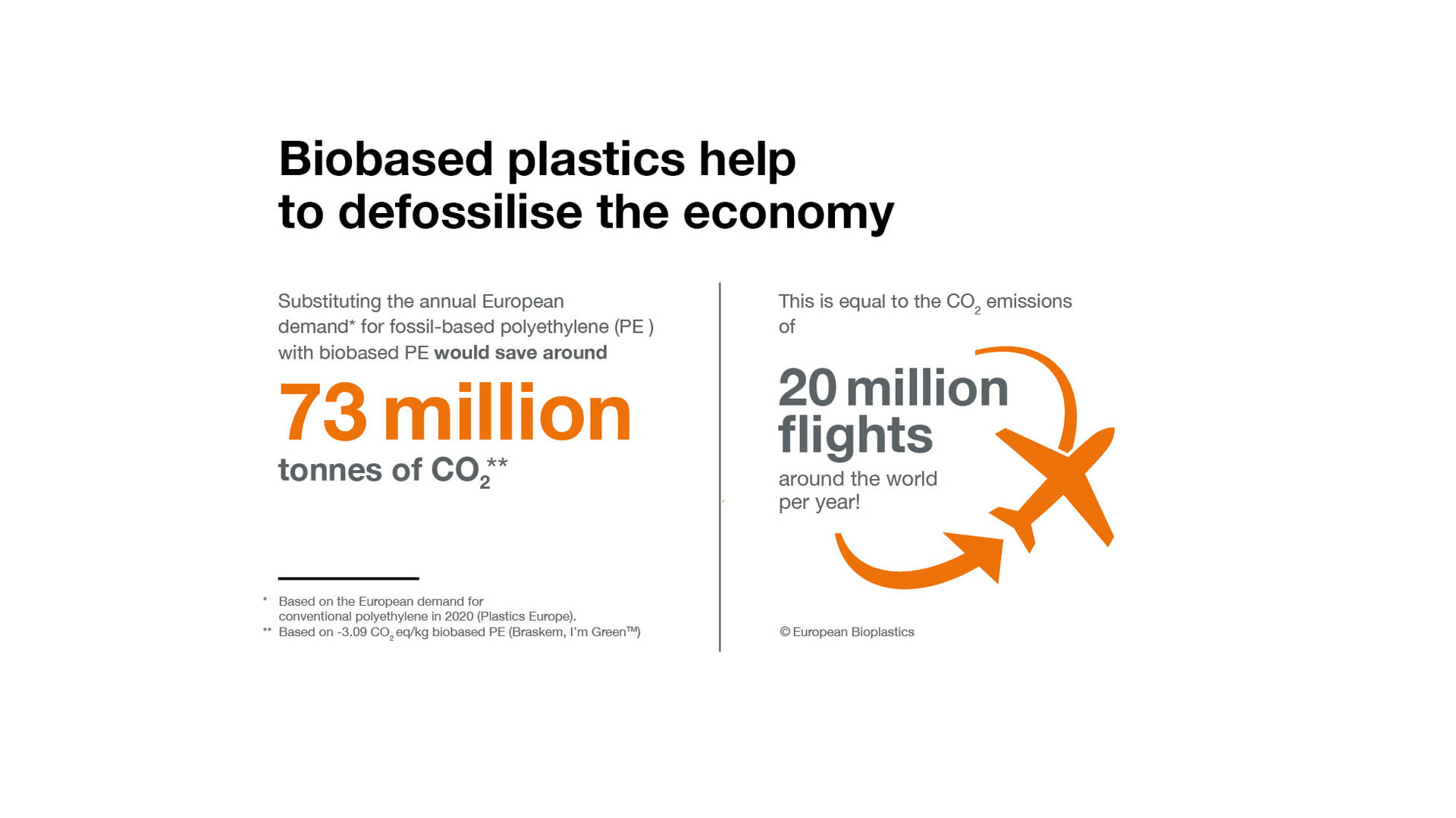

Climate neutrality – Europe’s ambition for 2050 – will only be achievable by cutting the emissions associated with the production, use and recycling of materials. They account for nearly one fifth of the total EU CO2 emissions. Biobased plastics can and will, if enabled, contribute towards this objective by storing and repurposing CO2, replacing the need for further fossil carbon extraction and the related environmental impacts. Biobased plastics are produced using renewable, plant-based feedstocks. Sustainably sourced renewable materials offer a key opportunity to help achieve Europe’s climate ambitions while supporting a sustainable economic development in EU’s rural areas.

Biobased and recycled content:

The Commission’s Communication on ‘Sustainable Carbon Cycles’ sets out the aspirational objective that at least 20% of the carbon used in chemical and plastic products should be from sustainable, non-fossil resources to help reaching climate neutrality. Focussing on recycling and reuse alone is not enough to replace the EU’s dependency on fossil resources and to reduce GHG emissions. Every product has a lifespan and losses are inherent to any recycling process. Virgin raw materials will therefore always be needed, especially when strict requirements on food safety and health must be met. To achieve a true circular economy, it is essential to substitute fossil-based, virgin materials with sustainably sourced biobased materials. Consequently, the Commission should promote a minimum biobased content to the same extend as recycled content in plastic products, such as the recycled content targets for plastic packaging set out in the proposal for a revised Regulation on Packaging and Packaging Waste (PPWR). Both, biobased and recycled content contribute to reduce the dependency on virgin fossil resources and GHG emissions, and they should be supported equally.

Methods to calculate and communicate biobased content:

When communicating with consumers, claims on ‘biobased’ plastics should refer to the share of biobased content in the product, stating for example that the ‘product contains 50% biobased content’. Claims on the biobased (carbon) content of a plastic product in B2C communication can only be made based on calculations using the C-14 (radiocarbon) method in line with the European standard EN 16785-1. Independent, third-party certification schemes for biobased content based on C-14, such as the TÜV Austria OK biobased scheme and the DIN CERTCO biobased scheme, already exist.

Product Environmental Footprint and Life Cycle Assessment approaches:

As the Commission plans to rely on the Product Environmental Footprint (PEF) and Life Cycle Assessment (LCA) methods as the guiding approach for environmental impact assessment, an accurate method to assess the carbon footprint of biobased products is critical. Yet, in the currently proposed PEF rules addressing biogenic carbon, there is no recognised benefit granted for the use of biogenic carbon at the beginning of the product life cycle. The JRC’s Plastics LCA method referenced in the policy framework does not even account for biogenic carbon uptake at all. Thus, as it stands, there is no appropriate incentive to use biobased resources, and these methods fail to appropriately assess the actual environmental benefits of biobased products. A lot more effort is needed to make PEF and LCA approaches fit for purpose. An updated method must provide for a balanced and fair evaluation and comparison of biobased and fossil-based products by awarding a carbon bonus at the stage of its uptake and giving a carbon malus when it’s released back into the atmosphere. The European Committee for Standardization CEN/TC 411 WG 4 is currently preparing a standard that intends to give clear guidelines for a comparative LCA of fossil-based and biobased products.

Long- vs. short-term biogenic carbon storage:

The Commission’s Communication states that priority should be given to long-lived products over short-lived products, including single-use applications. While we support such priority as it is necessary to tackle the challenges of waste reduction and sustainable use of resources, we insist that it must surely apply to all products, including conventional fossil-based plastic products. Biobased plastics are increasingly used in long-term products such as in the transport sector, building and construction sectors, fibres, and electronics. At the same time, certain short-term products and single-use applications might not be avoidable, especially when it comes to strict requirements on (food) safety, hygiene, and consumer health. These products should be encouraged to be manufactured from biobased renewable resources as this would still represent an improvement compared to conventional fossil-based materials.

Land use and competition for land used to produce food and feed:

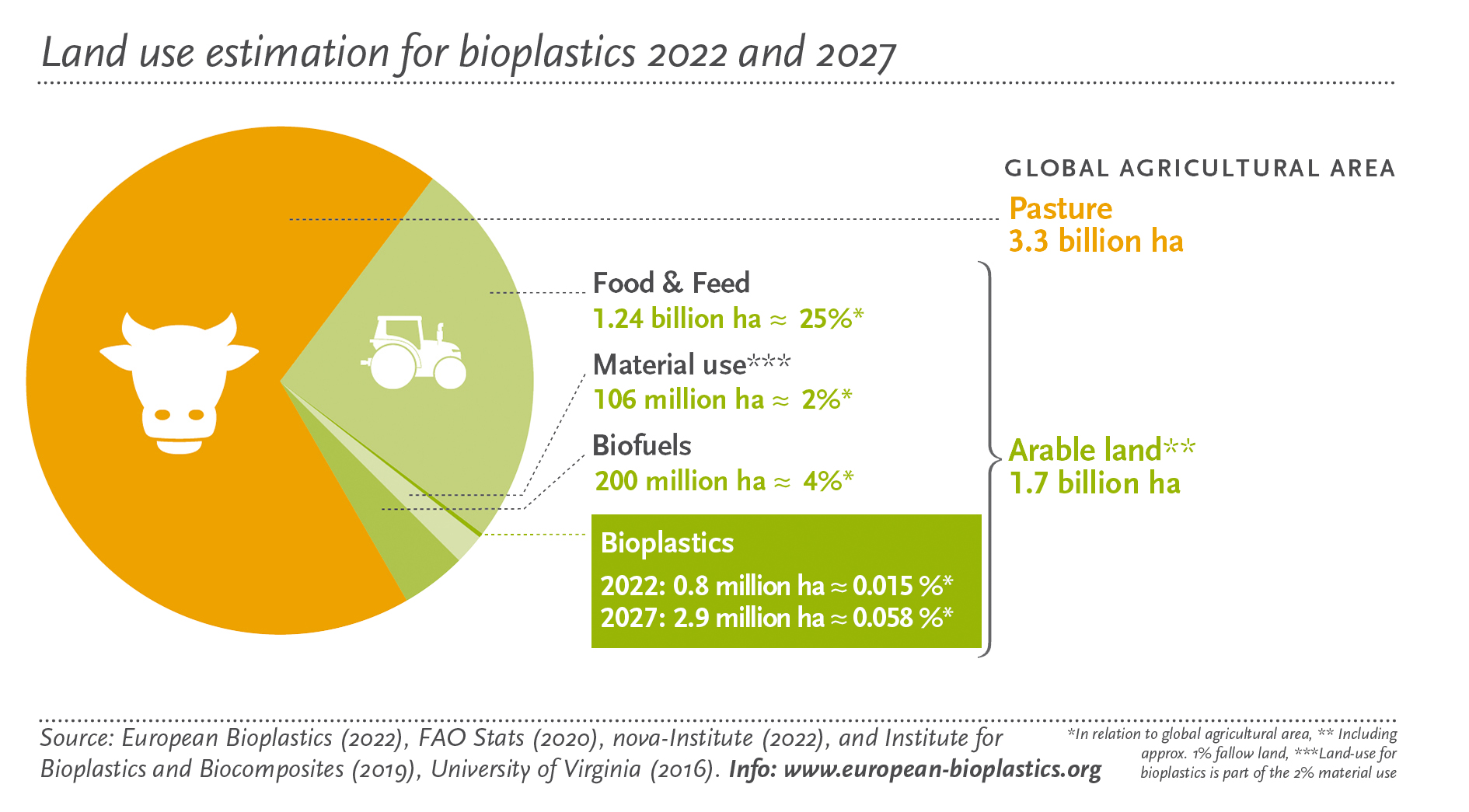

Despite the steep growth projection in the next years, the production of biobased plastics will not compete with land used to produce food and feed. In fact, food security and sustainability are two sides of the same coin and delivering on the green transition today is essential to ensure food security tomorrow. Current estimations show that not more than 0.06% of the global agricultural area will be used to produce biobased plastics in the coming years. Even if the entire current global plastics production were based on biomass feedstock – although such scenario is unrealistic – the demand for biomass would only be around 5% of the total amount of biomass produced and harvested around the globe each year.* These numbers show that there is no competition between the use of biomass for food, feed, and for material use.

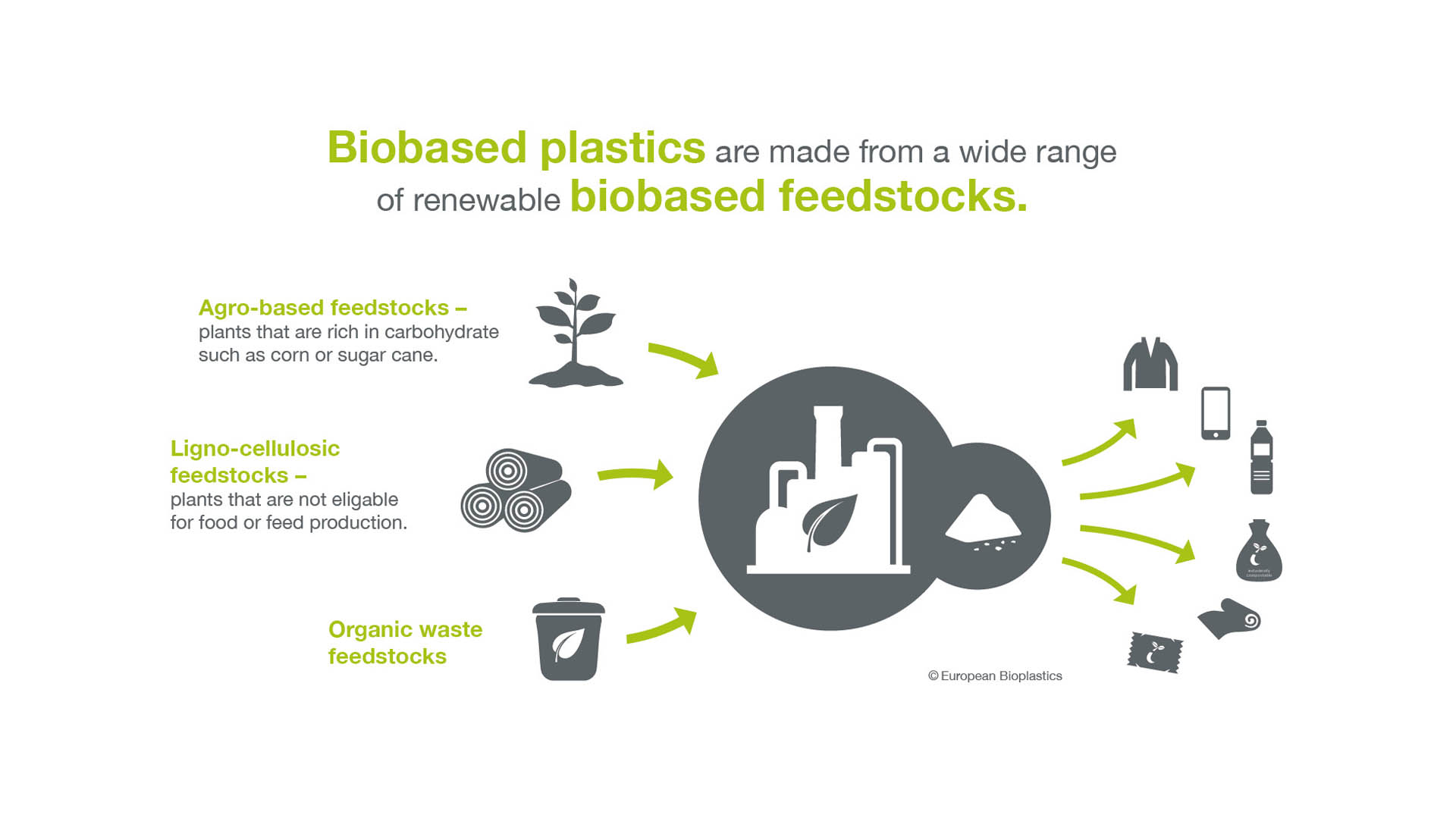

What is more, bioplastics made from agri-based feedstock will eventually facilitate the transition to later generations of feedstock. The industry is already looking into the use of non-food crops (from ligno-cellulosic feedstock), as well as waste products and side streams of the agricultural industry to produce biobased plastics.

Sustainability criteria:

Renewable feedstock that is suited for biofuels is, in general, also suited for making biobased plastics. Therefore, the application of the sustainability criteria applying to biofuels via the Renewable Energy Directive (RED) to biobased plastics is deemed appropriate, in principle. However, unlike biofuels, where one homogenous product is compared to another (fossil-based fuels), biobased plastics and the products derived from them are at least as diverse as the products made from conventional plastics. Therefore, comparative calculations on required GHG savings must take into consideration that there is not always an adequate equivalent fossil-based polymer or product to which the biobased polymer or product can be compared to. If comparisons with fossil-fuel derived plastics are to be fair, equal, and not anti-competitive, then sustainability criteria must be developed also for fossil-based feedstocks and processes.

More comments

Find out about the specific benefits of biodegradable and compostable plastics and the shortcomings of the Commission’s Communication …