- All

- About EUBP

- End-of-life

- Feedstock

- General questions

- Human health

- Market

- Material, properties and technology

- Mulch films

- Political framework

- Standardisation, certification, labelling

- Sustainability

Yes, when they adhere to the same strict European food contact regulations which are required for all plastics.

Related link:

To be able to use the CE marking on mulch films, companies must register their products with a notified body13 that performs a conformity assessment to ensure that all the requirements of the FPR are met. To prove conformity with certain requirements, the companies can provide already existing test reports from accredited labs in Europe. While the CE marking is unrelated to soil-biodegradability certifications, some of the required tests are the same, so the test reports of the certifications can be used in the conformity assessment via a notified body.

Related link:

Yes, “contrary to most other products harmonisation measures in Union law, the FPR does not replace national legislations and does not prevent non-harmonised fertilising products from being available on the single market in accordance with national legislations. Compliance with the harmonised rules as laid down in the FPR remains optional.”14 However, the biodegradable mulch films which are not certified according to FPR or national legislations on fertilisers are not to be considered fertilisers.

Related link:

Yes, other labels and claims can be applied as long as companies can prove what they are claiming. Thus, it is possible to include both the CE marking as well as labels to prove soil-biodegradability certification.

Related link:

The use of the CE marking is independent of current certifications for soil- biodegradability. It requires fulfilling the criteria which are set out in the Delegated Regulation 2024/278712. To fulfil the requirements for the CE marking, in addition to the tests required by certifications, the CE-marked mulch films need to pass a chronic earthworm toxicity test, a nitrification inhibition test, and a biodegradation test in an aquatic environment. The newly defined biodegradability criteria are strict but scientifically sound and will fully demonstrate that certified soil-biodegradable mulch films are environmentally safe while contributing to soil health and soil fertility.

Related link:

The inclusion of certified soil-biodegradable mulch films in the FPR opens a single market for producers and users (i.e., growers), guaranteeing by law a high level of soil protection.

Related link:

According to the FPR, a fertilising product is defined as: „a substance, mixture, micro- organism or any other material, applied or intended to be applied on plants or their rhizosphere or on mushrooms or their mycosphere, or intended to constitute the rhizosphere or mycosphere, either on its own or mixed with another material, for the purpose of providing the plants or mushrooms with nutrient or improving their nutrition efficiency.“ Furthermore, ‘EU fertilising product’ means „a fertilising product which is CE marked when made available on the market.”

Related link:

Biodegradable mulch films (according to the biodegradability criteria defined in the Delegated Regulation 2024/2787 of 23 July 2024) are included in the FPR as SOIL IMPROVER (PFC 3), and in particular as INORGANIC SOIL IMPROVER (PFC 3B). A soil improver is defined as „an EU fertilising product, the function of which is to maintain, improve or protect the physical or chemical properties, the structure or the biological activity of the soil to which it is added“. CE marked soil-biodegradable mulch films fulfill the requirement of SOIL IMPROVER, due to their characteristics of use: while they improve soil temperature and humidity during their use, once incorporated, they add organic carbon to the soil, which stimulates the microbial community.

Related link:

Certified soil-biodegradable mulch films are a specific type of mulch film used in agriculture to positively impact factors like temperature, moisture and weed growth to increase the crop yield and quality. They are made from certified soil-biodegradable materials in compliance with the biodegradability and ecotoxicity requirements as well as the technical specifications outlined in international standards (EN 17033:2018 and ISO 23517:2021) or certification schemes.(1)

In contrast to conventional mulch films, certified soil-biodegradable ones do not need to be removed but are ploughed under after the harvest where they will completely biodegrade in the soil.

(1) Complete biodegradation can be expected when a mulch film is certified in line with EN17033 and means that a minimum of 90% is converted to CO2 in 2 years. The remaining Carbon from the material will become part of the biomass.

Related link:

Mulch films made from cerified soil-biodegradable plastics provide significant benefits where retrieval and recycling of conventional plastics pose serious problems. They are specifically designed to biodegrade effectively in situ and can therefore be incorporated into the soil postharvest.

Due to their soil-biodegradability, certified soil-biodegradable mulch films help to stop leakage and the accumulation of microplastics in agricultural soils, unlike conventional plastics when these are not completely removed or properly disposed of. Especially thin nonbiodegradable mulch films (with thicknesses typically below 30 µm) have a poor collection and retrieval management, which can lead to a worrying level of plastic pollution in the fields.

Certified soil-biodegradable mulch films do not cause loss of agricultural topsoil. Even where conventional mulch films are removed from the fields, they are often heavily contaminated with soils and plant residues up to 60-80% of the initial weight of the film (see Figure 2 below). (2, 3)

Not only does the collection of non-biodegradable mulch films cause removal of topsoil (166 kt/yr in Europe) (4) , but it also inhibits the recycling process. Additionally, certified soil-biodegradable mulch films represent a useful tool to reduce plastic waste at source, since they avoid completely the production of a category of plastic waste difficult to be collected and disposed of in the first place.

Certified soil-biodegradable mulch films have been in use commercially since over 20 years, mainly for the cultivation of vegetable crops, where they have proved agronomic efficiency similar to the non-biodegradable mulch films (5) in terms of:

- Increase of soil temperature and retention of moisture leading to a better plant establishment and growth as well as early crop production compared to the bare soil,

- Reduction on the weed competition and better use of nutrients leading to a higher production and better quality of the crop compared to the bare soil,

- Increase in the development of a root system compared to bare soil, leading to a better crop development,

- Decrease in the use of phytosanitary products (specifically herbicides). (6, 7) Certified soil-biodegradable mulch films, thanks to their end-of-life characteristics, can as well be introduced as technical tools on crops such as maize, rice, vine, and processing tomato, which generally cannot benefit from the use of conventional mulches. (8)

(2) Briassoulis et al.: Experimental investigation of the quality characteristics of agricultural plastic wastes regarding their recycling and energy recovery potential. Waste Management 32(6): 1075–90.

(3) See Kasirajan, S., Ngouajio, M. Polyethylene and biodegradable mulches for agricultural applications: a review. Agron. Sustain. Dev. 32, 501–529 (2012) for an overview.

(4) Eunomia, Conventional and biodegradable plastics in agriculture, 2021; website: https:// www.eunomia.co.uk/reports-tools/conventional-and-biodegradable-plastics-inagriculture/

(5) Abbate C. et al., Agriculture 2023, 13, 197. https://doi.org/10.3390/agriculture13010197

(6) Tofanelli, M.B.D.; Wortman, S.E. Benchmarking the Agronomic Performance of Biodegradable Mulches against Polyethylene Mulch Film: A Meta-Analysis. Agronomy 2020, 10, 1618.

(7) Kasirajan, S., Ngouajio, M. Polyethylene and biodegradable mulches for agricultural applications: a review. Agron. Sustain. Dev. 32, 501–529 (2012).

(8) For vine: Emmanuelle Gastaldi, Francois Touchaleaume, G Cesar, Christophe Jourdan, P Coll, et al. Agronomic performances of biodegradable films as an alternative to polyethylene mulches in vineyards. Acta Horticulturae, 2019, XXI International Congress on Plastics in Agriculture: Agriculture, Plastics and Environment, 1252, 10.17660/ ActaHortic.2019.1252.4. hal-03706046

Related link:

Certified soil-biodegradable mulch films do fully biodegrade in soil. This can be proven by testing and referring to the standard EN 170339 (9) (or ISO 23517) (10), which specifies the requirements and test methods for biodegradable mulch films used in agriculture and horticulture. Products complying with that standard can get certification by DIN CERTCO. The label OK biodegradable SOIL is certified by TÜV AUSTRIA, Belgium, in case a product meets the requirement of their certification scheme.

For both certifications, the mulch film material must biodegrade in laboratory experiments, with a minimum of 90% conversion (absolute or relative to a positive control) of the carbon from the material into CO2 in no longer than 2 years at room temperature. This guarantees that soil microorganisms will be able to biodegrade the material in the soil and that no persistent microplastic will be left after disintegration.(11) Actual rates of biodegradation under real life field conditions will depend on several factors, such as material composition and thickness of the film. These parameters are usually used to adjust the properties according to the needs of the crop. In addition, water availability, soil composition, nutrients, and oxygen availability, as well as other climate and agricultural parameters, will influence the behaviour under real life conditions. This applies to certified soil-biodegradable mulch films just as much as to every other natural material. It is to be noted that, while very fast biodegrading materials might be seen as desirable from an end-of-life perspective, too fast biodegradation will make these materials unsuitable for the intended function, e.g. because of premature biodegradation before plant growth.

(9) EN 17033: Plastics – Biodegradable mulch films for use in agriculture and horticulture – Requirements and test methods.

(10) ISO 23517:2021: Plastics — Soil biodegradable materials for mulch films for use in agriculture and horticulture — Requirements and test methods regarding biodegradation, ecotoxicity and control of constituents.

(11) See: Maurizio Tosin et al., Disintegration and mineralization of mulch films and leaf litter in soil, Polymer Degradation and Stability, Volume 179, 2020

Related link:

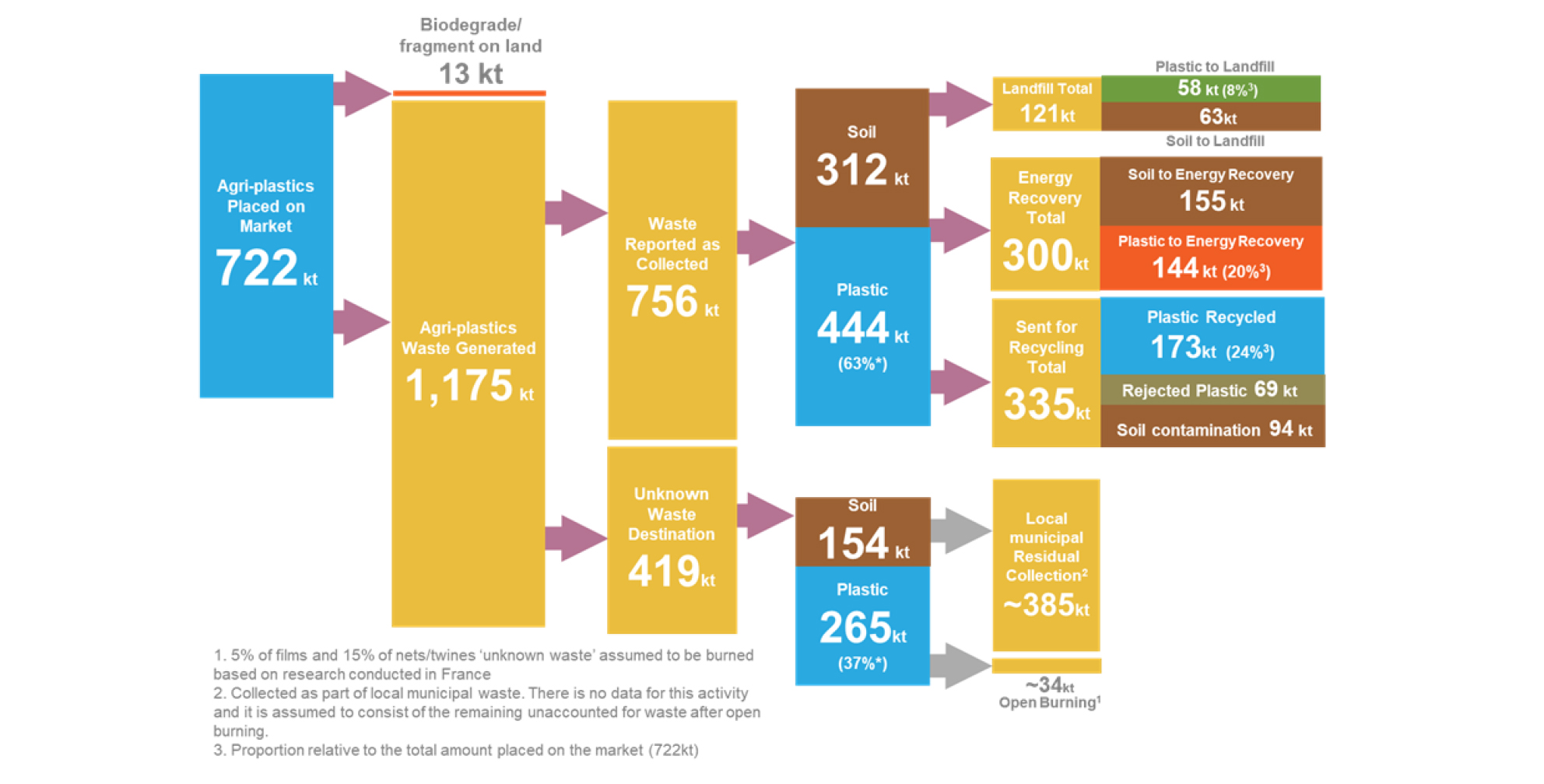

In Europe, over 720 kt/yr of agriculture plastics is used and only 24% of this is recycled. The main end-of-life for this plastic today is still landfilling. It is estimated that about 34 kt/yr of plastic materials are burned in the fields. Finally, about 950.000 ha of agricultural soil are polluted by plastic residues (see Figure 1). (12)

Figure 1. End-of-life of plastics materials for agriculture (Eunomia 2021)

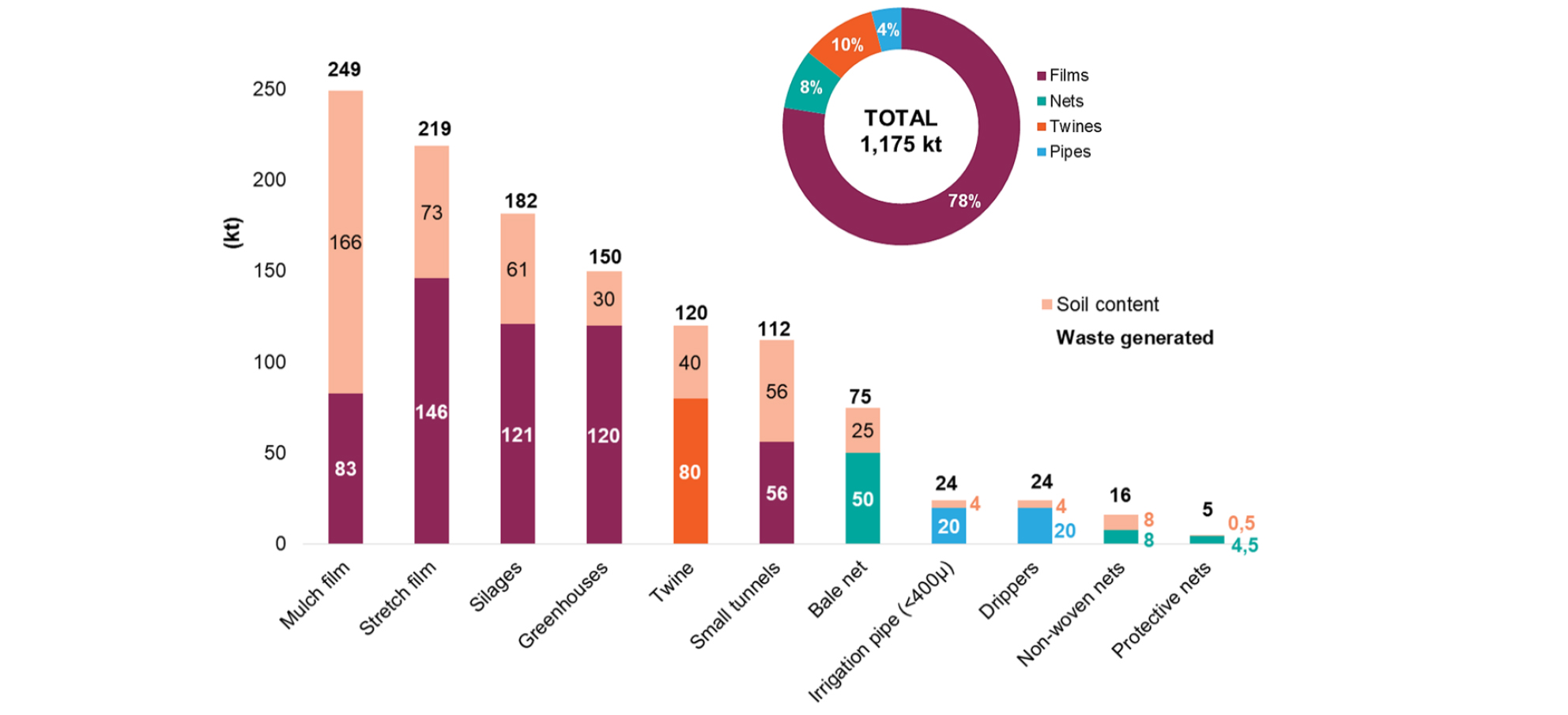

Mulch films, threads, and clips are the agricultural plastic applications with the most complicated collection and disposal, due to the amount of soil and other green waste, which is inseparably connected to these products at the end of their life in the field. Mulch films represent the second largest share of plastic films used in crop production in Europe (83 kt/yr) (13).

Figure 2. Soil content of main plastics applications (Eunomia,2021)

Figure 2. Soil content of main plastics applications (Eunomia,2021)

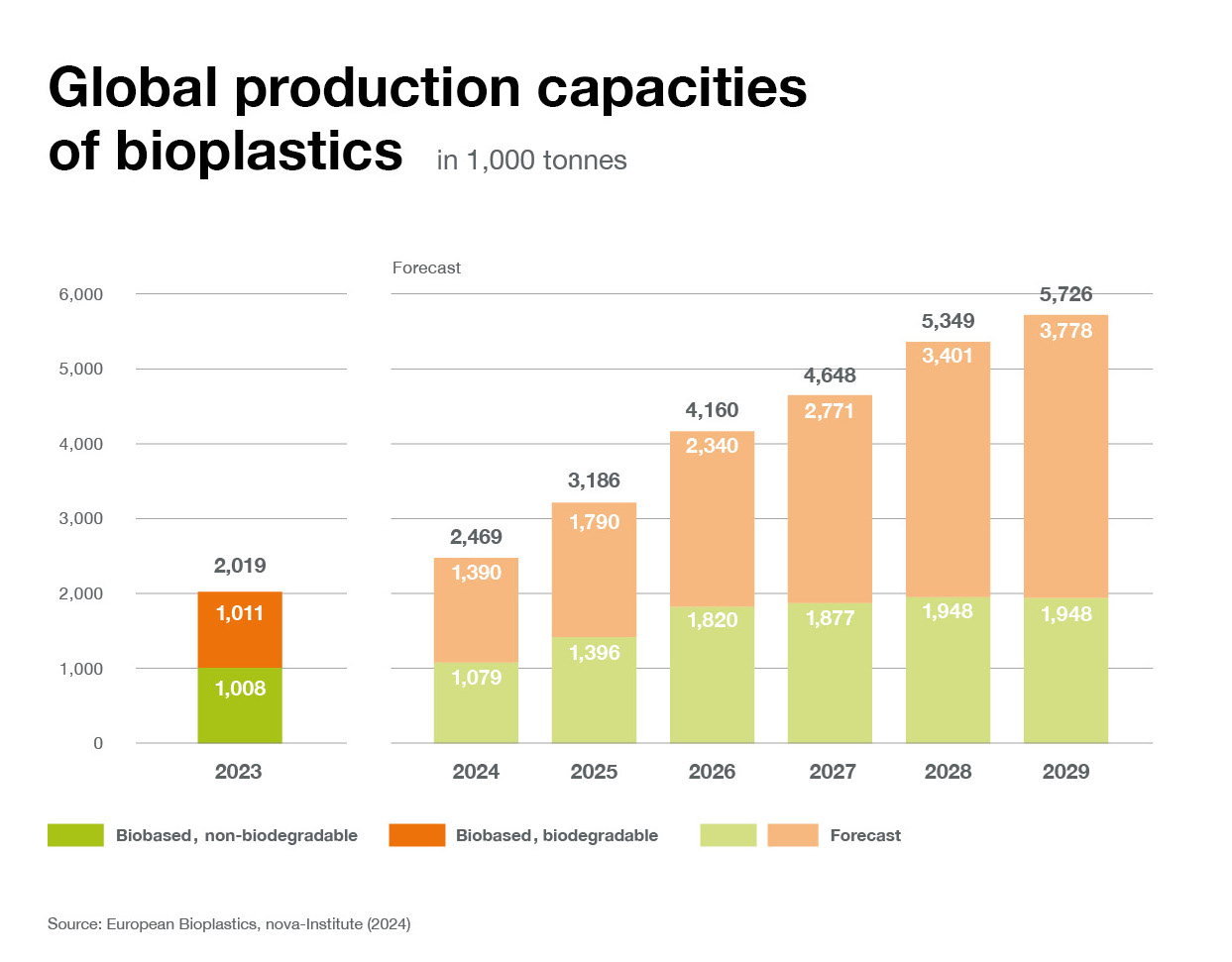

The materials used mostly in certified soil-biodegradable agricultural and horticultural applications are PHAs, PBAT, PBS, PCL, PLA, and starch. Of the global bioplastics production capacities in 2022, around 8% of certified soil-biodegradable materials were used for applications in agriculture and horticulture. This share is projected to reach 9% by 2027. There is an increased use of PHA and PLA for these applications, with the other polymers remaining rather stable.

In Europe, the production capacity for biodegradable materials grew from around 200,000 tonnes in 2011 to almost 390,000 tonnes in 2022 and is projected to reach more than 610,000 tonnes by 2027. (14)

In Germany, around 129 tonnes of certified soil-biodegradable mulch films are used per year in agriculture (compared to around 1,691 tonnes of conventional mulch film) (15).

In other countries, certified soil-biodegradable mulch films are already much more common. For example, 1.5kt/yr are used in Spain and 2kt/yr in Italy. (16)

(12) Data taken from Eunomia: Conventional and Biodegradable Plastics in Agriculture. July 2021

(13) Eunomia, Conventional and biodegradable plastics in agriculture, 2021; website: https:// www.eunomia.co.uk/reports-tools/conventional-and-biodegradable-plastics-inagriculture/

(14 ) European Bioplastics market data, available online: https://www.european-bioplastics. org/news/publications/#MarketData

(15) Bertling, Jürgen; Zimmermann, Till; Rödig, Lisa: Kunststoffe in der Umwelt: Emissionen in landwirtschaftlich genutzten Böden, Oberhausen, Fraunhofer UMSICHT (2021)

(16) Eunomia, Conventional and biodegradable plastics in agriculture, 2021; website: https:// www.eunomia.co.uk/reports-tools/conventional-and-biodegradable-plastics-inagriculture/

Related link:

Biodegradable mulch films that are certified for soil-biodegradability (e.g. in line with EN 17033 or ISO 23517) are fully biodegradable, i.e. they are converted into CO2, H2O, and biomass. (17, 18)

This is guaranteed through the mandatory laboratory biodegradation tests required by the certification (90% mineralization absolute or relative to a positive control within 2 years’ time in soil at ambient temperature, preferably 25 °C). To be biodegraded by soil microorganisms, certified soil-biodegradable mulch films need to first disintegrate into smaller particles. These are then further biodegraded in soil, with rates depending on the environmental conditions and agricultural practices. Fragments from certified soilbiodegradable mulch films should not be confused with microplastics generated by conventional mulch films, such as polyethylene. The latter would lead to plastic accumulation in soil in case of repeated applications and incomplete collection. A recent study shows that transient particles produced by natural polymers and biodegradable materials are not to be equated with particles formed by polymers which are resistant to biodegradation. The study compared the behaviour of three materials: a certified soilbiodegradable mulch film, cellulose (natural polymer known to be biodegradable), and a non-biodegradable mulch film (HDPE). The results showed that microplastic from non-biodegradable materials persist in the environment and accumulate, while fragments generated from certified soil-biodegradable mulch films and cellulose are quickly biodegraded by microbes. (19)

(17) See OWS: Expert statement (bio)degradable mulching films, 2017, available online: https://docs.european-bioplastics.org/publications/OWS_Expert_statement_mulching_ films.pdf

(18) Maurizio Tosin et al.: Disintegration and mineralization of mulch films and leaf litter in soil. Polymer Degradation and Stability, Volume 179, 2020.

(19) Francesco Degli-Innocenti et al.: Analysis of the microplastic emission potential of a starch-based biodegradable plastic material, 2022, available online: https://doi. org/10.1007/s10532-023-10031-8

Related link:

Certified soil-biodegradable mulch films pass comprehensive ecotoxicity testing and strict thresholds concerning other harmful substances. The required testing includes plant growth test, acute or chronic earthworm test, and nitrification inhibition testing. These tests are performed on partially or completely biodegraded materials, therefore covering also the impact of degradation products, such as e.g. fragments. Additionally, there are strict rules when it comes to the usage of regulated metals, SVHCs, and PFAS.

Related link:

Agricultural products certified as soil-biodegradable will biodegrade in soil. Such products are designed for agricultural purposes and should be used accordingly. Conscientious and thorough application prevents parts of the mulch films from leaking into other environments than soil. The film is buried in the soil at the sides and, if necessary, covered with soil in several places. In addition, thorough ploughing under after harvesting is indispensable for the biodegradation process.

Biodegradability in the open environment (especially marine) is desirable only for very few, highly specific, applications. These could be applications that would be difficult to find and recover, such as firework casings, or applications intended to be used by professionals like farmers or fishermen/fisherwomen (e.g. certain fishing gear) under specific circumstances. For products intended to biodegrade in marine environments, international standards defining marine biodegradability of plastic items will have to be developed, as currently being done in ISO and ASTM level.

For other applications the property of being biodegradable in the open environment is neither to be promoted nor endorsed, and concerned industry fully agrees that this principle should not change. However, if an overall assessment of the persistence of items that are of consequence for “littering” is to be carried out, it should incorporate a risk assessment for all materials that can be found in the open environment, including conventional plastics.

Related link:

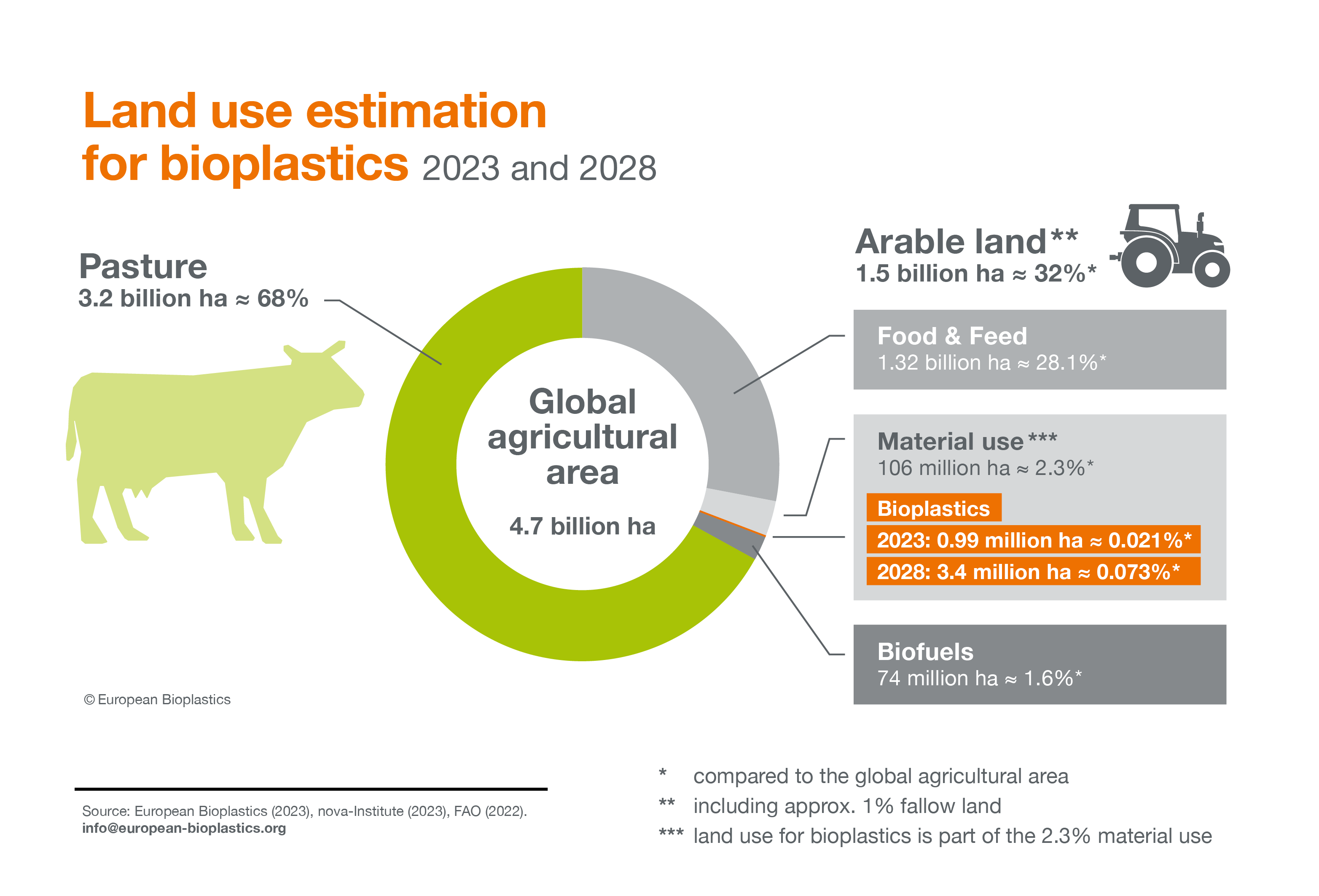

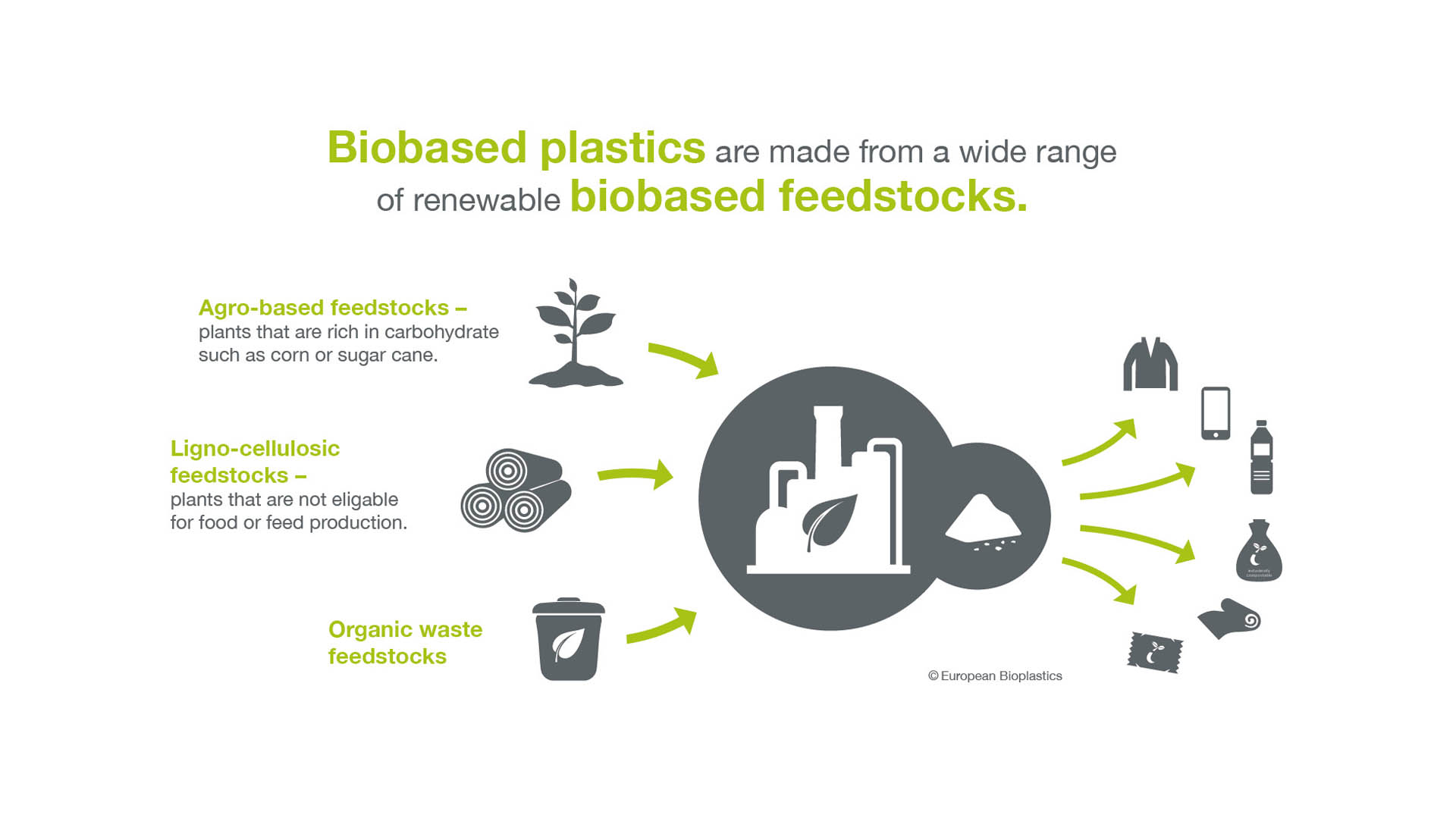

Today, biobased plastics are mostly made from carbohydrate-rich plants, such as corn or sugar cane, so called agro-based feedstock (20). Currently, agro-based generation feedstock is the most efficient feedstock to produce biobased plastics as it requires the least amount of land to grow on and produces the highest yields. The feedstock currently used to produce bioplastics relies on less than 0.02% of the global agricultural area – compared to 96% of the area used for pasture and the production of food and feed. Despite the predicted continued growth in the bioplastics market at the current stage of technological development, the share of global agricultural area needed to grow feedstock to produce biobased plastics will only slightly increase to still below 0.07% by 2028. This clearly demonstrates that there is no competition between food/feed and bioplastic production.

(20) Agro-based feedstock is often referred to as 1st generation feedstock.

Related link:

Even though LCA is the most systematic way to understand the interrelation between a product system and the environment (including biodegradable products), some specific issues, related to the nature of biodegradable products, require a more detailed way to be properly addressed. Current LCA methodologies cannot be considered fully fit for purpose when it comes to comparing certified soil-biodegradable mulch films with traditional ones. LCA results are greatly case-dependent and influenced by numerous choices. Product characteristics, system boundaries and LCA modelling need to be carefully considered to allow a realistic assessment. If done so, as shown in a study by the European Commission certified soil-biodegradable mulch films perform significantly better than conventional mulch films on a cradle-to-grave basis for seven out of eight impact categories for which a comparison was possible. The ameliorative results of biodegradable mulch films, including categories like acidification and eutrophication, were also possible thanks to a lower consumption of plastic required (due to the lower thickness) and the absence of a removal and disposal phase as required for traditional mulch films.

When performing comparative LCA’s on mulch films, numerous points need to be taken into consideration, as for example:

- Removed mulch films are usually heavily soiled and often additionally polluted with pesticides and fertilisers, therefore making recycling a difficult option

- Soil organic carbon is removed together with natural nutrients

- Microplastics accumulation of non-biodegradable mulch films

- Non-removal results in reduced energy need

- Certified soil-biodegradable mulch films already passed comprehensive ecotoxicity testing and strict thresholds concerning other harmful substances in line with EN17033

Related link:

Biodegradation is a chemical process in which materials are metabolised to CO2, water, and biomass with the help of microorganisms. The process of biodegradation depends on the conditions (e.g. location, temperature, humidity, presence of microorganisms, etc.) of the specific environment (industrial composting plant, garden compost, soil, water, etc.) and on the material or application itself. Consequently, the process and its outcome can vary considerably.

Related links:

Compostable plastics that are tested and certified according to the European standard for industrial composting EN 13432 are required to disintegrate after 12 weeks and completely biodegrade after six months. That means that 90 percent or more of the plastic material will have been converted to CO2. The remaining share is converted into water and biomass, which no longer contains any plastic. EN 13432 also includes test on ecotoxicity and heavy metal contents to ensure that no harmful substances are left behind.

Companies already involved in the bioplastics business sector but not yet a member of European Bioplastics should consider the advantages of connecting to our information and business platform and enlarging their network. Newcomers to our industry and/or the European market in particular can rely on European Bioplastics to help them get a foothold in the sector and benefit from our broad knowledge and contact database.

A membership offers access to a multitude of networking opportunities, visibility through representation across the field, business enhancement opportunities and support, access to comprehensive information resources, annual meetings and conference discounts.

The services available exclusively to members of European Bioplastics, include (but are not limited to):

- A ‘members only’ knowledge database including reports, political communiqués and financial programmes;

- Public relations and marketing measures and activities that increase awareness for bioplastics and our members’ brands and products;

- Participation in association meetings and the opportunity to propose points of action for adoption;

- Matchmaking/consulting services through European Bioplastics, which create synergies between companies looking for specific services within the bioplastics sector;

- Reduced entry fees to industry events organised by European Bioplastics, and – where applicable – the opportunity to present products and network at the association’s booth.

For more details, please see the membership benefits leaflet or our statutes and membership fee code and membership application form.

Related links:

The European bioplastics industry has a strong record for developing innovative technological solutions and aligning industrial objectives with environmental sustainability. In order for Europe to reinforce its position as a front-runner of resource efficiency and green growth, forward-looking sectors with strong environmental credentials and growth potential, such as bioplastics, need to be promoted.

European Bioplastics has identified a number of key issues at political and regulatory level that will need to be addressed to ensure that the bioplastics sector can unfold its full environmental, economic, and social potential in Europe. These key issues are:

- Guaranteeing access to competitively priced agricultural feedstock and biomass in sufficient quantities and quality, and establishing a level playing field for industrial use of biomass with an integrated EU policy approach for material and energy uses of biomass and feedstock.

- Providing financial and political support through supportive market mechanisms similar to the “BioPreferred programme” in the United States or national investment programmes in several countries in South-East Asia. Additionally, Europe should further encourage a market shift towards increased production and use of biobased products, in order to support and stimulate industry in Europe. This could involve incentivising the use of biobased materials or putting a price tag on fossil carbon through carbon pricing mechanisms.

- Raising awareness and informing consumers about the importance of a transition to a biobased circular economy and the benefits and essential role of products such as bioplastics in that shift.

Related links:

Currently there is no EU law in place applying specifically to biobased, biodegradable and compostable plastics. Yet, the European Union has made increasing efforts to introduce or adapt policies, regulatory frameworks, and standards to strengthen and implement the bioeconomy and circular economy in Europe in recent years, all of which affect the bioplastics sector in one way or other.

In particular, the future policy framework for biobased, biodegradable and compostable plastics, as part of the Commission’s Circular Economy Action Plan and Green Deal, is a crucial piece of legislation. It has the potential to boost the role of bioplastics in developing a truly circular bioeconomy, enabling innovation, and attracting new investments. Currently, there is no legislation in place at EU level specifically designed for our industry. Hence, the implications of the new policy framework for the bioplastics sector will be extremely important.

European top-level strategies supporting bioplastics:

- EU Bioeconomy Strategy (2018)

- EU Plastics Strategy (2018)

- EU Green Deal (2019)

- New EU Circular Economy Action Plan (2020)

- EU Climate Law (2021) & EU Taxonomy (2020)

- Packaging & Packaging Waste Directive (review 2022)

- Waste Framework Directive (review 2023)

Other relevant policy initiatives include:

- Single-Use Plastics Directive (2019) incl. restrictions on oxo-degradable plastics

- EU rules on recycled plastics for food-contact materials (2022)

- Substantiating claims on environmental performance (2022)

- Sustainable Products Initiative (2022) / Proposal on ecodesign for sustainable products Regulation

- Policy Framework for biobased, biodegradable and compostable plastics (2022)

- Sustainable Carbon Cycles (2021)

The European Green Deal (2019) is nothing less than the EU’s committment to making Europe climate neutral by 2050. The plan is to review each existing law, and to introduce new legislation on the circular economy, building renovation, biodiversity, farming, and innovation. The Deal plans to decouple economic growth from resource use, to set ambitious greenhouse gas emissions reduction targets (zero net emissions by 2050), carbon pricing mechanisms, and the decarbonisation of the energy system. In the deal, the Commission specifically foresees the adaption of a new Circular Economy Action Plan with strong focus on the plastics sector, especially “sustainable products” and a circular design for all products. However, the Commission should be cautious to not solely focus on mandatory provisions for recycled content, which hampers other innovative pathways of material innovation that help achieve zero net emissions. Alternative sustainable feedstocks such as biobased feedstocks need to be encouraged as well to reduce dependency on fossil resources.

In 2018, the European Commission adopted the first EU strategy for plastics with the overall aim to contribute to the transition towards a carbon neutral circular economy. It sets goals to curb plastic waste, to increase resource efficiency, and to create value and job growth in Europe. It highlights the importance of biodegradable and compostable plastics in separate collection systems for organic waste to improve clean waste streams and recycling quality.

Furthermore, the Commission’s Sustainable Products Initiative (2022) and the Ecodesign for Sustainable Products Regulation (ESPR) proposal will be the cornerstone of EU environmental policy and will have a major impact on product design and market access. Published on 30 March 2022, the proposal builds upon the “Ecodesign Directive” which currently only covers energy related products. The Commission is proposing a general framework as well as sector specific legislation for different product categories. Ecodesign requirements will be adopted through delegated acts for each product group. The Commission will publish a preliminary work plan for the next 3 years, with the timeline for the publication for the Delegated Acts.

Related links:

Environmental claims of bioplastic products should be specific, accurate, relevant and truthful. Furthermore, there should be independent third party substantiation for these claims.

A label awarded in accordance with independent certification based on acknowledged standards guarantees that the product fulfils the criteria claimed. As bioplastics cannot be distinguished from conventional plastics by non-experts, reliable labelling helps the consumer to identify these products. It also informs the consumer of particular additional qualities the material or product possesses. Another advantage provided by compostability labels in particular is that they facilitate correct waste separation, collection and recovery.

Related links:

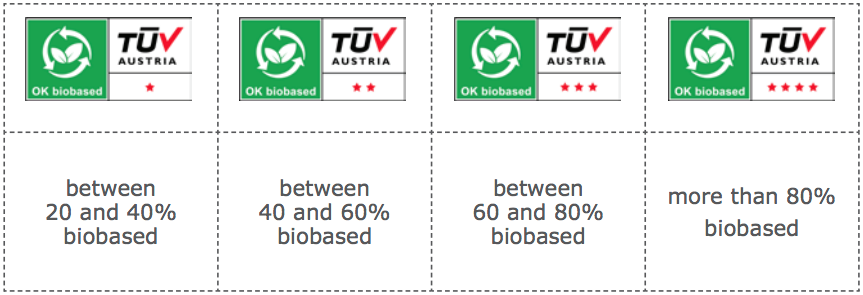

Labels referring to the biobased content are for example DIN-Geprüft biobased, OK biobased (both offering different labels reflecting the product’s share of biobased content), and the new logo by Nederlandse Norm (NEN), based on EN 16785-1.

Labels for industrially compostable products are, for example, the Seedling Logo, OK Compost, and DIN-Geprüft Industrial Compostable.

Labels proving home compostability are OK compost Home and the DIN-Geprüft Home Compostable Mark.

The label OK biodegradable Soil is certified by TÜV AUSTRIA Belgium in case a product meets the requirement of their certification scheme. DIN CERTCO awards DIN-Geprüft biodegradable in soil in accordance with CEN/TR 15822.

Figure: The EUBP-Seedling, a biobased label by DIN CERTCO and OK biodegradable SOIL by TÜV AUSTRIA Belgium

Related links:

Certification of biodegradable/compostable products is available from TÜV AUSTRIA Belgium and DIN CERTCO (Germany) or one of its co-operating institutes such as AfOR (UK) and COBRO (Poland). The Seedling logo for industrial compostable plastic packaging (based on EN 13432) can be acquired from TÜV AUSTRIA Belgium or DIN CERTCO following successful certification.

Certification for biobased products based on EN 16640 is available from DIN CERTCO (Germany) and TÜV AUSTRIA Belgium.

A standard can be used as the basis for a certification scheme if it clearly defines the criteria and the testing procedures for the material or product. Once the certifier confirms compliance with the defined requirements, the respective product can be labelled with the corresponding logo.

Working Group 3 of the Technical Committee (TC) 411 of CEN has developed different standards for the measurement of the renewable content of biobased materials and, therefore, bioplastics. Most importantly, the European norm EN 16640 „Biobased products – Determination of the biobased carbon content of products using the radiocarbon method“, published in 2017, describes how to measure the carbon isotope 14C (radiocarbon method). In addition, the standard EN 16785-1 „Biobased products – Biobased content – Part 1: Determination of the biobased content using the radiocarbon analysis and elemental analysis“ has been developed to also account for other biobased elements in a polymer through elemental analysis.

EN 13432 “Requirements for packaging recoverable through composting and biodegradation” is the European standard for biodegradable packaging designed for treatment in industrial composting facilities and anaerobic digestion. It requires at least 90% disintegration after twelve weeks and includes tests on ecotoxicity and heavy metal content.

There is currently no international standard specifying the conditions for home composting of biodegradable plastics. However, there are several national standards, such as the Australian norm AS 5810 “Biodegradable plastics – biodegradable plastics suitable for home composting” as well as the French standard NF T 51-800 “Plastics — Specifications for plastics suitable for home composting” requires at least 90% degradation in 12 months at ambient temperature.

A new standard EN 17033 “Biodegradable mulch films for use in agriculture and horticulture – Requirements and test methods” (expected to be published in 2017) specifies the requirements for biodegradable films, manufactured from thermoplastic materials, to be used for mulching applications in agriculture and horticulture, which are not intended to be removed. A degradation of at least 90% in two years at preferably 25°C will be required.

Comparing two different products is difficult as the materials (fossil-based and bio-based) and production processes vary widely, and current assessment tools and methods are limited in their ability to make sound, substantiating comparisons. Whereas the carbon footprint of products (CFP or PCF – product carbon footprint ISO/TS 14067) of two products can be compared, the life cycle assessments (LCAs, ISO 14040 and 14044, EN 16760) of two different products may have limited significance as they can consider different impact categories, differ in scope, and leave ample room for interpretation. A sound comparison based on LCA can, however, be made for one product when switching from fossil to bio-based plastics as a way to assess the environmental impact of the product before and after the switch. Such comparison will clearly show where the bio-based solution is advantageous as long as it is conducted in the same way considering the exact same impact categories.

Biobased plastics have the unique advantage to reduce the dependency on fossil resources, curb greenhouse gas (GHG) emissions, and increase resource efficiency. They are also an essential part of the bioeconomy which is worth 2.3 trillion euros in annual turnover and employs 16 million people in the EU. Although, compared to conventional plastics, the production of bioplastics is still small (less than 1 percent of the entire global plastics production), the potential for growth and further innovation and development is enormous. These yet untapped opportunities for the bioplastics industry and the positive environmental, and socio-economic effects need to be considered when assessing the environmental impact of bioplastics – especially when compared to established conventional plastics. Currently, there are two meaningful indicators that sustainability assessments of bioplastics should focus on, as they rely on common methodologies and standards:

- biobased/renewable content (EN 16440, EN 16785-1 /-2, ASTM 6866)

- reduction of greenhouse gas emissions (ISO/TS 14067, GHG Protocol, PAS2050).

Life cycle assessments (LCAs) are an important tool for substantiating environmental claims (ISO 14040 and 14044) as they take into account many different factors such as energy use, GHG emissions, and water use. In order to get a complete picture of a product’s impact on the environment, the complete life cycle must be considered. Yet, LCAs can only shine a spotlight on a single product. They are not suitable for comparing different products as materials (e.g., fossil-based and biobased) and processes vary widely, limiting the ability to make sound, substantiated comparisons.

Related links:

Biobased plastics have the unique advantage over conventional plastics to reduce the dependency on limited fossil resources and to reduce greenhouse gas emissions. Plants sequester atmospheric carbon dioxide (CO2) during their growth. Using these plants (renewable biomass) to produce biobased plastics removes CO2 from the atmosphere and keeps it stored throughout the entire product life. This carbon fixation (carbon sink) can be extended for even longer if the material is recycled.

Substituting the annual global demand for fossil-based polyethylene (PE) with biobased PE would safe more than 73 million tonnes of CO2. This equals the CO2 emissions of 20 million flights aground the world per year.

The carbon footprint of a product (CFP) can be measured by carbon footprinting or the life cycle assessment (LCA, standard ISO 14040 and ISO 14044). Information on how a carbon footprint should be established is set out in the ISO 14067 standard entitled the “Carbon Footprint of Products” published in 2013.

Related links:

Biobased plastics have the same properties as conventional plastics but also feature the unique advantage to reduce the dependency on limited fossil resources and to potentially reduce greenhouse gas emissions. Consequently, biobased plastics can help to decouple economic growth from the resource depletion and help the EU to meet its 2020 targets of greenhouse gas emissions reduction. Moreover, bioplastics can make a considerable contribution to increased resource efficiency through a closed resource cycle and use cascades, especially if biobased materials and products are being either reused or recycled and eventually used for energy recovery (i.e. renewable energy).

When it comes to sustainability, according to a study by the German Environment Agency “bioplastics are at least as good as conventional plastics”. The study also mentions that “considerable potential is yet untapped” (ifeu/GEA, 2012).

Related links:

Bioplastics are a large family of different materials with widely varying properties. Drop-in solutions, such as biobased PE or biobased PET can be mechanically recycled in established recycling streams. Biodegradable and compostable plastics can be organically recycled (industrial composting and anaerobic digestion). All bioplastics can also be treated in recovery streams (incineration and the production of renewable energy due to the biobased origin). As with conventional plastics, the manner in which bioplastics waste is recovered depends on the type of the product, the bioplastics material used, as well as the volumes and recycling and recovery systems available.

Studies have shown that there is little risk posed by biodegradation of biodegradable plastics in landfills (Kolstad, Vink, De Wilde, Debeer: Assessment of anaerobic degradation of Ingeo® polylactides under accelerated landfill conditions, 2012). Most bioplastics remain inert in landfills.

Landfilling remains a widely applied method of waste treatment in Europe. Forty-two percent of all post consumer plastics waste in Europe is still buried in landfills, which means that the material value or the energy value of the waste remain unused. Therefore, European Bioplastics supports a restriction on landfilling of recyclable plastic waste in Europe in favour of strengthening measures to strengthen the recycling and recovery of plastics.

Marine litter is one of the main threats to the environment. The largest share of marine litter consists of plastics that originate from a variety of sources, including shipping activities, ineffectively managed landfills, and public littering. In order to minimise and ultimately prevent further pollution of the marine environment, the full implementation of EU waste legislation and an increase in the efficiency of waste management around the globe are crucial. Moreover, the introduction of a Europe-wide ban on landfilling for plastic products and appropriate measures to expand recycling and recovery of plastic waste are necessary.

In areas where separate biowaste collection exists, compostable biowaste bags can help divert biowaste – including the bags in which it is collected – from landfills, thereby reducing the amount of plastic bags entering into the marine environment in the first place. Yet, biodegradable plastics should not be considered a solution to the problem of marine litter. Littering should never be promoted or accepted for any kind of waste, neither on land nor at sea – including all varieties of plastics. Instead, the issue needs to be addressed by educative and informative measures to raise awareness for proper and controlled ways of management, disposal, and recycling.

The UNEP report on ‘bioplastics and marine litter’ (2015) recognises that polymers, which biodegrade on land under favourable conditions, also biodegrade in the marine environment. The report also states, however, that this process is not calculable enough at this point in time, and biodegradable plastics are currently not a solution to marine litter. European Bioplastics (EUBP) agrees with the report’s call for further research and the development of clear standards for biodegradation in the marine environment. Currently, there is no international standard available that appropriately describes the biodegradation of plastics in the marine environment. However, a number of standardization projects are in progress at ISO and ASTM level on how to test marine biodegradation processes.

Related links:

A product should always be designed with an efficient and appropriate recovery solution in mind. In the case of biodegradable plastic products, the preferable recovery solution is the separate collection together with the biowaste, organic recycling (e.g. composting in industrial composting plant or anaerobic digestion in AD plants), and hence the production of valuable compost or biogas. European Bioplastics does not support any statements that advertise bioplastics as a solution to the littering problems. Littering refers to careless discarding of waste and is not a legitimate means of disposal.

Biodegradable plastics are often regarded as a possible solution to this problem as they can be decomposed by microorganisms without producing harmful or noxious residue during decomposition. However, the process of biodegradation is dependent on certain environmental conditions (i.e. temperature, presence of microorganisms, timeframe, etc.). Products suitable for industrial composting (as defined according to the European standard for industrial compostability EN 13432) are fit for the conditions in a composting plant, but not necessary for those outside in nature.

Littering should never be promoted for any kind of material or waste. It is imperative for the consumer to continue to be conscious of the fact that no matter what type of packaging or waste, it must be subject to appropriate disposal and recovery processes.

Related links:

Biodegradation is defined as the biochemical process by which materials metabolise completely to water, carbon dioxide, and biomass with the help of microorganisms. However, the term “biodegradable” is not valuable if the timeframe and the conditions are not specified and related scientific data is not provided. Currently, there are no known, scientifically reliable test results for enzyme-mediated plastics, which provide evidence for biodegradability or compostability. Likewise, there has not been any documentation of enzyme-mediated plastic fulfilling the criteria of the EN 13432 (European standard for industrial compostability) standard.

Related links:

Enzyme-mediated plastics usually neither look nor feel different from conventional plastics. However, when a product carries claims such as “this plastic degrades faster”, or “makes conventional plastics like PE or PP biodegradable” together with “organic additives” and “eco-friendly”, it is likely that the material is an enzyme-mediated plastic.

Related links:

Enzyme-mediated plastics are not bioplastics. They are not biobased and they are not proven to be biodegradable or compostable in accordance with any standard*. Enzyme-mediated plastics are conventional, non-biodegradable plastics (e.g. PE) enriched with small amounts of an organic additive. The degradation process is supposed to be initiated by microorganisms, which consume the additives. It is claimed that this process expands to the PE, thus making the material degradable. The plastic is said to visually disappear and to be completely converted into carbon dioxide and water after some time, which could not yet been proven by any available study.

* “Biodegradability” refers to a process during which microorganisms from the environment convert materials into natural substances such as water, carbon dioxide and biomass without the use of artificial additives.

Related links:

Truly biodegradable plastics can be distinguished from so-called ‘oxo-fragmentable’ plastics through the use of labels and certification that adhere to acknowledged industry standards for biodegradation. The European standard for industrial compostable packaging EN13432, for example, is such a clear and specific option, and corresponding certification and labels such as the ‘Seedling’ logo (according to EN 13432) are available to substantiate the claims of biodegradability and compostability.

So-called ‘oxo-fragmentable’ products are made from conventional plastics and supplemented with specific additives in order to mimic biodegradation. In truth, however, these additives only facilitate a fragmentation of the materials, which do not fully degrade but break down into very small fragments that remain in the environment.

Biodegradability is an inherent characteristic of a material or polymer. In contrast to oxo-fragmentation, biodegradation results from the action of naturally occurring microorganisms. The process produces water, carbon dioxide, and biomass as end products.

Oxo-fragmentable materials do not biodegrade under industrial composting conditions as defined in accepted standard specifications such as EN 13432, ISO 18606, or ASTM D6400.

Compostable plastics that are tested and certified according to the European standard for industrial composting EN 13432 are required to disintegrate after 12 weeks and completely biodegrade after six months. That means that 90 percent or more of the plastic material will have been converted to CO2. The remaining share is biomass, which no longer contains any plastic. EN 13432 also includes test on eco-toxicity and heavy metal contents to ensure that no harmful substances are left behind.

Very short composting cycles may not be sufficient to allow for a full disintegration of some types of biowaste as well as for some compostable plastic packaging. However, leftover scraps (usually ligno-cellulosics) in composting plants are sifted out and added to the next fresh compost batch for another composting cycle where they fully metabolise to water, carbon dioxide, and biomass.

Related links:

Using biodegradable and compostable plastic products such as biowaste bags or fresh food packaging increases the end-of-life options. In addition to recovering energy and mechanical recycling, industrial composting (organic recycling) becomes an available end-of-life option.

Compostability is a clear benefit when plastic items are mixed with biowaste. Under these conditions, mechanical recycling is not feasible, neither for plastics nor biowaste. The use of compostable plastics makes the mixed waste suitable for organic recycling (industrial composting and anaerobic digestion), enabling the shift from recovery to recycling (a treatment option which ranks higher on the European waste hierarchy). This way, biowaste is diverted from other recycling streams or from landfill and facilitating separate collection – resulting in the creation of more valuable compost.

Related links:

Industrial composting is an established process with commonly agreed requirements concerning temperature and timeframe for biodegradable waste to metabolise to stable, sanitised products (biomass) to be used in agriculture (humus/fertiliser). This process takes place in industrial or municipal composting plants. These plants provide controlled conditions, i.e. controlled temperatures, humidity, aeration, etc. for a quick and safe composting process.

The criteria for the industrial compostability of packaging are set out in the European standard EN 13432. EN 13432 requires the compostable plastics to disintegrate after 12 weeks and completely biodegrade after six months. That means that 90 percent or more of the plastic material will have been converted to CO2. The remaining share is converted into water and biomass – i.e. valuable compost. Materials and products complying with this standard can be certified and labelled accordingly.

There is currently no international standard specifying the conditions for home composting of biodegradable plastics. However, there are several national standards, such as the Australian norm AS 5810 “Biodegradable plastics – biodegradable plastics suitable for home composting”. Belgian certifier TÜV Austria Belgium had developed the OK compost home certification scheme, requiring at least 90% degradation in 12 months at ambient temperature. Based on this scheme, the French standard NF T 51-800 “Plastics — Specifications for plastics suitable for home composting” was developed, specifying the very same requirements for certification.

Biodegradation is a chemical process in which materials are metabolised to CO2, water, and biomass with the help of microorganisms. The process of biodegradation depends on the conditions (e.g. location, temperature, humidity, presence of microorganisms, etc.) of the specific environment (industrial composting plant, garden compost, soil, water, etc.) and on the material or application itself. Consequently, the process and its outcome can vary considerably.

In order to be recovered by means of organic recycling (composting) a material or product needs to be biodegradable. Compostability is a characteristic of a product, packaging or associated component that allows it to biodegrade under specific conditions (e.g. a certain temperature, timeframe, etc). These specific conditions are described in standards, such as the European standard on industrial composting EN 13432 (for packaging) or EN 14995 (for plastic materials in general). Materials and products complying with this standard can be certified and labelled accordingly.

Please note that in order to make accurate and specific claims about compostability the location (home, industrial) and timeframe need to be specified.

No. Bioplastics are a large family of materials that can be either biobased, biodegradable or both. Biobased, non-biodegradable (durable) materials have a share of 43.7 percent. The largest share (56.3 percent) of bioplastics currently on the market are biodegradable materials. Biodegradability is an inherent property of certain polymers that can be preferable for specific applications (e.g., biowaste bags).

Biodegradable/compostable products should feature a clear recommendation regarding the suitable end-of-life option and correct disposal for this product. European Bioplastics recommends acquiring a certificate and according label for biodegradable plastic products meant for industrial composting according to EN 13432.

Compostable plastics that are tested and certified according to the European standards for industrial composting EN 13432 (for packaging) or EN 14995 (for plastic materials in general) fulfil the technical criteria to be treated in industrial composting plants. These plants provide controlled conditions, i.e. controlled temperatures, humidity, aeration, etc. for a quick and safe composting process.

EN 13432 requires for the compostable plastics to disintegrate after 12 weeks and completely biodegrade after six months. That means that 90 percent or more of the plastic material will have been converted to CO2. The remaining share is converted into water and biomass – i.e. valuable compost.

Compost is used as a soil improver and can in part also replace mineral fertilisers.

Organic recycling is defined by the EU Packaging and Packaging Waste Directive 94/62/EC (amended in 2005/20/EC) as the aerobic treatment (industrial composting) or anaerobic treatment (biogasification) of packaging waste.

The EU Directive refers to the harmonised European standard for the industrial compostability of plastic packaging: EN 13432. An equivalent standard has been approved by the European standardisation organisation CEN for the testing of compostability of plastics: EN 14995.

In order to make organic recycling of biodegradable packaging more effective, a mandatory separate collection of biodegradable waste and legal access for certified compostable products to enter the respective recycling systems would be needed.

As with conventional plastics, bioplastics need to be recycled separately (by stream type). Available sorting technologies such as NIR (near infrared) help to reduce contamination.

Bioplastic materials for which a recycling stream already exists (e.g. biobased PE and biobased PET) can easily be recycled together with their conventional counterparts. Other bioplastics for which no separate streams yet exist, are very unlikely to end up in mechanical recycling streams due to sophisticated sorting and treatment procedures (positive selection). Innovative materials such as PLA can technically easily be sorted and mechanically recycled. Once sufficiently large volumes are sold on the market, the implementation of separate recycling streams for PLA will become economically viable for recyclers.

If a separate recycling stream for a certain plastic type exists, the bioplastic material can simply be recycled together with their conventional counterpart – e.g. biobased PE in the PE-stream or biobased PET in the PET stream – as they are chemically and physically identical in their properties.

The post consumer recycling of bioplastics materials for which no separate stream yet exists, will be feasible, as soon as the commercial volumes and sales increase sufficiently to cover the investments required to install separate recycling streams. It is expected, that new separate recycling streams for PLA for example will be feasible and introduced in the short to medium term.

Bioplastics are a diverse family of materials. Depending on the material and the application, recycling in existing waste streams is certainly an option. Drop-in solutions such as biobased PE or biobased PET can easily be recycled in existing recycling streams together with their conventional counterparts. Innovative materials such as PLA can also be mechanically recycled. Once sufficient volumes are on the market, the establishment of a separate recycling stream will become feasible. Biodegradable plastic products that have been certified compostable according to EN 13432 are suitable for industrial composting. All bioplastic materials offer (renewable) energy recovery as they contain a high energy value.

Related links:

European Bioplastics and its members are committed to avoiding the use of harmful substances in their products. Many plastic products do not use any plasticisers but a range of acceptable plasticisers is available if necessary. The wide range of bioplastics is based on thousands of different formulas. This means specific information regarding a certain material or product can only be obtained from the individual manufacturer, converter or brand owner using the material.

If GM crops are used for the production of biobased plastics, the multiple-stage processing and high heat used to create the polymer remove all traces of genetic material. This means that the final bioplastic product contains no traces of GMO. Should the bioplastic be used for e.g. food packaging, this packaging will be well suited for the purpose as it contains no genetically modified material and cannot interact with the contents. However, most bioplastics in the market are made from GMO-free feedstock.

Sustainable sourcing of feedstock is a prerequisite for more sustainable products.

That is why European Bioplastics supports:

- the general sparing use of resources and increase of resource efficiency (e.g. through use cascades),

- the implementation of good agricultural practice,

- corresponding third-party certification, and

- a responsible choice of feedstock: The use of food residues or by-products of (food) crops can contribute to more sustainable sourcing. In addition, the biorefinery concept is promising in transforming cellulosic, non-food biomass feedstock into a variety of chemicals, e.g. ethanol, lactic acid, or many others, which can also be used to manufacture bioplastics.

Sustainable sourcing of the renewable feedstock and good agricultural practices and technologies are continuously enhanced and ensured through the emergence of reliable and independent sustainability certification schemes such as ISCC Plus, RSB, or REDcert.

Related links:

The use of genetically modified (GM) crops is not a technical requirement for the production of any bioplastic materials that are commercially available today. If GM crops are used, the reasons usually lie in the regional feedstock supply situation or are based on economic decisions.

Most bioplastics producers do not use GMO feedstock for the production of their biobased plastic materials or offer GMO-free options. Yet, even if GM crops are used for the production of bioplastics, the multiple-stage processing and high heat used to create the polymer removes all traces of genetic material. This means that the final bioplastic product contains no genetic traces. The resulting bioplastic product is therefore well suited to use in food packaging as it contains no genetically modified material and cannot interact with the contents.

Yes, to some extend. Today, bioplastics are predominantly produced from agro-based feedstock (i.e. plants that are rich in carbohydrates). At the same time, the bioplastics industry is investing in the research and development to diversify the availability of biogenic feedstock for the production of biobased plastics. The industry particularly aims to further develop fermentation technologies that enable the utilisation of ligno-cellulosic feedstock sources, such as non-food crops or waste from food crops, in the medium and long term. The production of ligno-cellulosic sugars and ethanol in particular are regarded as a promising technological approach.

There are various ways to ensure a sufficient supply of biomass for the production for food, feed, and industrial/material uses (including bioplastics) now and in future. These include:

- Broadening the base of feedstock: The bioplastics industry is currently working mostly with agro-based feedstock (i.e. plants that are rich in carbohydrate, such as corn or sugar cane). Several projects, however, are already looking into using plant residues or other lingo-cellulosic feedstock.

- Increasing yields: Increasing the efficiency of industrial conversion of raw materials into feedstock, for example by using optimised yeasts or bacteria and optimised physical and chemical processes would increase the total availability of resources.

- Taking fallow land into production: There is still plenty of arable land in various geographical regions available for production, even in the European Union.*

* Different sources come up with varying figures for „free“ arable land, the French National Institute For Agricultural Research gives 2.6 billion hectares of untapped potential (article in ParisTech, 2011), the nova-Institute calculates 570 million hectares based on figures of OECD and FAO (2009). The bottom line – there is an ample amount of unused land available.

According to the FAO, about one third of the global food production is either wasted or lost every year. European Bioplastics acknowledges that this is a serious problem and strongly supports efforts to reduce food waste.

Other deficiencies that need to be addressed are:

- logistical aspects such as poor distribution/storage of food/feed,

- political instability, and

- lack of financial resources.

When it comes to using biomass, there is no competition between food or feed and bioplastics. The land currently needed to grow the feedstock for the production of bioplastics amounts to only about 0.02 percent of the global agricultural area – compared to 96 percent of the area that is used for pasture and the production of food and feed.

Agro-based feedstock – plants that are rich in carbohydrates, such as corn or sugar cane, is currently the most efficient and resilient feedstock available for the production of bioplastics. Other solutions, such as non-food crops or waste from food crops that are providing ligno-cellulosic feedstock, will be available in the medium and long term.

There is no well-founded argument against a responsible and monitored (i.e. sustainable) use of food crops for bioplastics. There is even evidence that the industrial and material use of biomass may in fact serve as a stabilizer for food prices, providing farmers with more secure markets and thereby leading to more sustainable production. Independent third party certification schemes can help to take social, environmental and economic criteria into account and to ensure that bioplastics are a purely beneficial innovation.

The feedstock currently used for the production of bioplastics relies on only about 0.013 percent of the global agricultural area – compared to 97 percent of the area, which is used for the production of food and feed. This clearly demonstrates that there is no competition between food/feed and industrial production.

Of the 13.4 billion hectares of global land surface, around 38 percent (5 billion hectares) is currently used for agriculture. This includes pastures (67 percent, approx. 3.2 billion hectares). The arable land is divided into areas predominantly used for growing food crops and feed (31.4 percent, approx. 1.5 billion hectares), as well as crops for materials (0.7 percent, approx. 33 million hectares, including the 624,000 hectares used for bioplastics, 0.013%)* , and crops for biofuels (0.8 percent, approx. 39 million hectares).

Moreover, advanced integrated production processes, for example in biorefineries, are already able to produce several different kinds of products out of one specific feedstock – including products for food, feed, and products, such as bioplastics.

*The 0.7 percent comprise e.g. natural fibers (primarily cotton), rubber, bamboo, plant oils, sugar and starch. Of these 33 million hectares only 624,000 hectares are used to grow feedstock for bioplastics (primarily sugar and starch).

Today, bioplastics are mostly made from carbohydrate-rich plants, such as corn or sugar cane, so called agro-based or 1st generation feedstock. Currently, 1st generation feedstock is the most efficient feedstock for the production of bioplastics as it requires the least amount of land to grow on and produces the highest yields.

The feedstock currently used to produce bioplastics relies to a little bit more than 0.01 percent of the global agricultural area (4.7 billion hectares) – compared to 96 percent of the area, which is used for pasture and the production of food and feed. Despite the predicted continued growth in the bioplastics market at the current stage of technological development, the share of global agricultural area used to grow feedstock for the production of bioplastics will only slightly increase to still below 0.07 percent in 2028. This clearly demonstrates that there is no competition between food/feed and industrial production.

A report by Wageningen Food & Biobased Research (Biobased and biodegradable plastics – Facts and figures, 2017) calculates that “even if we would base all present world-wide fossil plastics production on biomass as feedstock instead, the demand for feedstock would be around 5 percent of the total amount of biomass produced and harvested each year”. Yet, this scenario is unlikely to happen, as the bioplastics industry is also looking into the use of non-food crops (ligno-cellulosic feedstock), such as wood, straw, as well as waste products and side streams of the agro-industry to produce bioplastics. Using an increased share of food residues, non-food crops or cellulosic biomass could lead to even less land needed for bioplastics than the numbers given above.

The emerging shift from crude oil towards renewable resources is driven primarily by the sustainable development efforts of the plastics industry. Finite oil resources and climate change constitute two broadly acknowledged challenges for society in the coming decades. Reducing the dependency on oil and mitigating the effects of climate change are therefore two important drivers for the use of renewable resources for the production of plastics. Biobased plastics have the unique advantage over conventional plastics to reduce the dependency on limited fossil resources and to reduce greenhouse gas emissions.

Using biomass that is sustainably sourced and regrows on an annual basis is a major environmental benefit of biobased plastic products. Plants sequester carbon dioxide during their growth and convert it into carbon-rich organic matter. When these materials are used in the production of bioplastics the carbon is stored within the products during their useful life, which can be prolonged if the products are being recycled. This carbon is eventually released back into the atmosphere through energy recovery or composting. Consequently, biobased plastics can help the EU to meet its 2020 targets of greenhouse gas emissions reduction.

Moreover, bioplastics can make a considerable contribution to increased resource efficiency through a closed resource cycle and use cascades, especially if biobased materials and products are being either reused or recycled and eventually used for energy recovery (i.e. renewable energy).

Today, there is a bioplastic alternative for almost every conventional plastic material and corresponding application. Bioplastics – plastics that are biobased, biodegradable, or both – can have the same properties as conventional plastics and offer additional advantages, such as a reduced carbon footprint or additional waste management options such as industrial composting.

Some bioplastics offer additional functionalities, such as biodegradability or compostability, and improved properties, such as increased heat resistance, enhanced moisture or gas barriers, greater stiffness and flexibility or improved durability.

Bioplastics are available in a wide variety of types and compounds that can mostly be converted on the standard equipment generally used for processing conventional plastics.

Related links:

There is no common agreement on a minimal value yet due to varying regional regulations in Europe. In Japan an industry-wide commitment sets the “biomass margin” at “25 percent renewable material”. According to the USDA Bio-preferred Programme, “the minimum share of renewable material ranges from 7 to 95 percent” depending on defined product category rules.

Although there is no minimum value, acknowledged labelling options for biobased plastics are available to clearly and transparently indicate the biobased content of a material or product. The certifiers TÜV AUSTRIA Belgium and DIN CERTCO offer a progressive certification scheme and according labels based on the European standard EN 16640 or ISO 16620-2 (or ASTM D 6866), which provide proof the biobased carbon content of a material or product.

Figure: Labels depicting the biobased content of a bioplastic product.

Bioplastics are a diverse family of materials with differing properties. There are three main groups:

- Biobased (or partially biobased), durable plastics such as biobased polyethylene (PE), polyethylene terephthalate (PET) (so-called drop-in solutions), biobased technical performance polymers, such as numerous polyamides (PA), or (partly) biobased polyurethanes (PUR);

- Biobased and biodegradable, compostable plastics, such as polylactic acid (PLA), polyhydroxyalkanaoates (PHA), polybutylene succinate (PBS), and starch blends;

- Plastics that are based on fossil resources and are biodegradable, such as PBAT and PCL, but that may well be produced at least partly biobased in the future.

Biobased, durable plastics, such as biobased PE or biobased PET, possess properties that are identical to their conventional versions. These bioplastics are technically equivalent to their fossil counterparts; yet, they can help to reduce a product’s carbon footprint. Moreover, they can be mechanically recycled in the according existing recycling streams.

Innovative materials such as PLA, PHA, or starch-based materials offer solutions with completely new functionalities such as biodegradability and compostability and in some cases optimised barrier properties.

Along with the growth in variety of bioplastic materials, properties such as flexibility, durability, printability, transparency, barrier, heat resistance, gloss and many more have been significantly enhanced.

Related links:

Today, bioplastics are mostly made of carbohydrate-rich plants such as corn, sugar cane or sugar beet – so-called food crops or first generation feedstock. First generation feedstock is currently the most efficient for the production of bioplastics, as it requires the least amount of land to grow and produces the highest yields.

The bioplastics industry is also researching the use of non-food crops (second and third generation feedstock), such as cellulose, with a view to its further use for the production of bioplastics materials. Innovative technologies are focussing on non-edible by-products of the production of food crops, which generates large amounts of cellulosic by-products such as straw, corn stover or bagasse that can be used to produce biopolymers.

The increase in the use of bioplastics is driven by an increasing demand for sustainable products by consumers due to a growing awareness of the impact on the environment. To the environmentally conscious customer, the advantages of being biobased give bioplastics the competitive edge to conventional plastics. About 80 percent of European consumers want to buy products with a minimal impact on the environment (Eurobarometer survey, European Commission, 2013) and brands and companies turn to bioplastic solutions to respond to these demands.

What is more, according to the German Agency for Renewable Resources (FNR) and the Straubing Center of Science (2009), consumers want to see more products made from bioplastics on the market. Yet, consumers are not always very well informed about bioplastics, which leads to some misunderstandings and wrong expectations about the nature of bioplastics and poses a challenge for bioplastics penetrating the consumer market. Joint efforts by the bioplastics industry and brands to inform about bioplastic materials and products are however contributing towards an increased awareness and better understanding of bioplastics amongst consumers.

Related links:

The number of brand owners that apply bioplastics in their solutions is growing steadily.

Prominent examples of big brands that have introduced bioplastic packaging are Danone, Coca-Cola (PlantBottle), and Ecover (cleaning products). The supermarket chains Carrefour, Sainsbury, Billa, Spar and Hofer offer different packaging products and/or shopping bags made of bioplastics. In the leisure/sport sector PUMA, for example, uses bioplastics, and in the automotive market, Ford, Toyota and Mercedes have introduced various bioplastic components in several car models. In the consumer electronics market, Fujitsu is a well known brand that uses bioplastics in some of its products.

Related links:

Bioplastics have a multitude of durable but also short-lived applications. Durable, biobased commodity plastics such as biobased PE or biobased PET are used for short-life applications such as packaging as well as for long-lasting applications such as car parts, toys, or consumer electronics that can be easily recycled in existing streams. These so called ‘drop-in solutions’ represent the largest sector of global bioplastics production.

Innovative biobased and biodegradable materials such as PLA, PHA or starch blends are suitable for long-lasting products but are mainly used in short-lived applications such as packaging. They offer solutions with completely new functionalities such as compostability and in some cases optimised barrier properties for a prolonged shelf life and thus preventing food waste.

Related links:

Today, there is pretty much nothing that bioplastics can’t do. For almost every conventional plastic material and application, there is a bioplastic alternative available that offers the same or in some cases even better properties and functionalities. Today, bioplastics are mainly being used in the following market segments:

- Packaging

- Food-services

- Agriculture & horticulture

- Consumer electronics

- Automotive & transport

- Consumer goods and household appliances

- Building & construction

- Coating & adhesives

- Fibers

The latest market data analysis by European Bioplastics shows that packaging remains the largest fields of application for bioplastics with 45 percent of the total bioplastics market in 2024. The data also confirms a decisive increase in the uptake of bioplastics materials in many other sectors, including consumer goods and applications in the automotive and transport sector, and the construction and building sector, where technical performance polymers are being used.

The cost of research and development still makes up for a share of investment in bioplastics and has an impact on material and product prices. Additionally, the currently low oil prices are making it difficult for bioplastics to achieve competitive pricing levels compared to conventional plastics at present. However, prices have continuously been decreasing over the past decade. As more companies and brands are switching to biobased plastics, and as production capacities are rising, supply chains and processes are becoming more efficient, and prices have come down significantly. With rising demand and more efficient production processes, increasing volumes of bioplastics on the market and oil prices expected to rise again, the costs for bioplastics will soon be comparable with those for conventional plastic prices.

Moreover, specific material properties of bioplastic materials can allow for a reduction of the overall volumes of materials needed for a product or application as well as for cost reduction in the use or end-of-life phase. Already today, there are several examples of cost competitive bioplastic materials and products.

Related links:

With the right legislative framework and market conditions in place, the European bioplastics industry could offer an immense employment growth potential. From 23,000 employees in 2013, the bioplastics industry could grow to 300,000 high-skilled jobs in 2030. The bioplastics industry could provide new impulses for the development of rural areas in Europe by presenting new opportunities for the agricultural sector and consequently contribute to the reindustrialisation and employment growth in Europe. Feasibility studies showed that bioplastics could technically substitute about 85 percent of all conventional plastics (according to PRO BIP study conducted by the University of Utrecht in 2009), even though this is not a realistic short- or mid-term development, it illustrates that bioplastics will be a significant part of the overall plastics market in the future.

Related links:

In 2013, the bioplastics industry accounted for 23,000 jobs in Europe. With the right framework conditions in place, this number could increase more than tenfold by 2030, with up to 300,000 high-skilled jobs being created in the European bioplastics sector.

Related links:

As an important part of the bioeconomy, bioplastics are a future lead market for the European Union offering job creation, development of rural areas and global export opportunities for innovative technologies.

According to a recent job market analysis conducted by EuropaBio, the European bioplastics industry could realise a steep employment growth over the next decades. In 2013, the bioplastics industry accounted for around 23,000 jobs in Europe. With the right framework conditions in place, this number could increase more than tenfold by 2030, with up to 300,000 high-skilled jobs being created in the European bioplastics sector.

The European bioeconomy sectors are worth 2 trillion euros in annual turnover and account for 22 million jobs in the EU. That is approx. 9 percent of the EU’s workforce.

Related links:

Today, there is pretty much nothing that bioplastics can’t do. For almost every conventional plastic material and application, there is a bioplastic alternative available that offers the same or in some cases even better properties and functionalities. The main challenge faced by the bioplastics industry is not of technical nature but the lack of effective policy measures or regulatory incentives to encourage a full-scale market entry. According to a PRO BIP study conducted by the University of Utrecht in 2009, bioplastics could technically substitute around 85 percent of conventional plastics. To make all plastics from biobased materials is not a realistic short- or mid-term development.

Related links:

Supply is well ensured to meet the growing demand in the short and medium term. However, it is difficult to make long-term forecasts due to the dynamic and innovative nature of the bioplastic market. A reliable legislative framework in the EU would be beneficial to further attract investment and ensure supply in the long run.