Environmental benefits of bioplastics

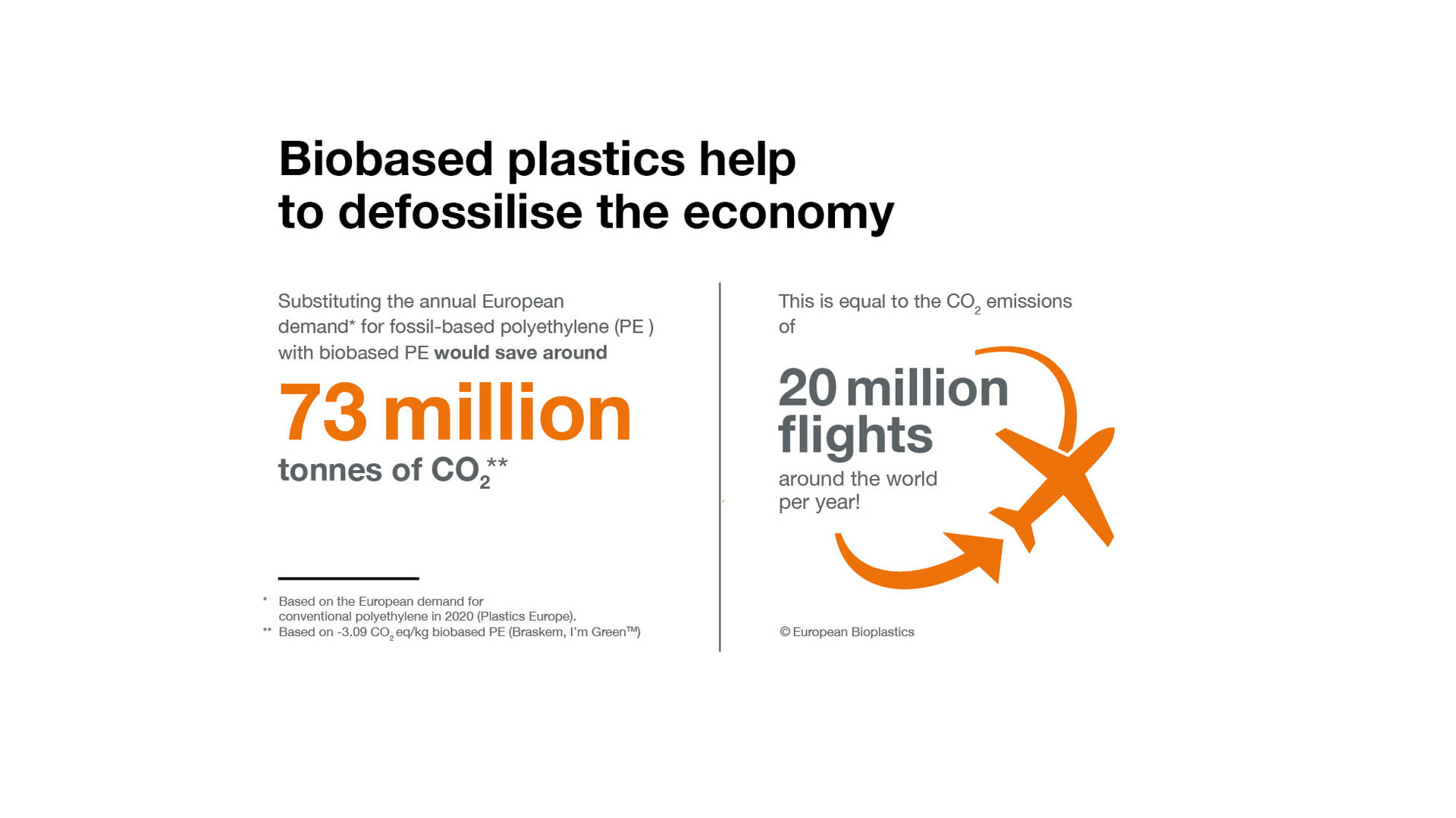

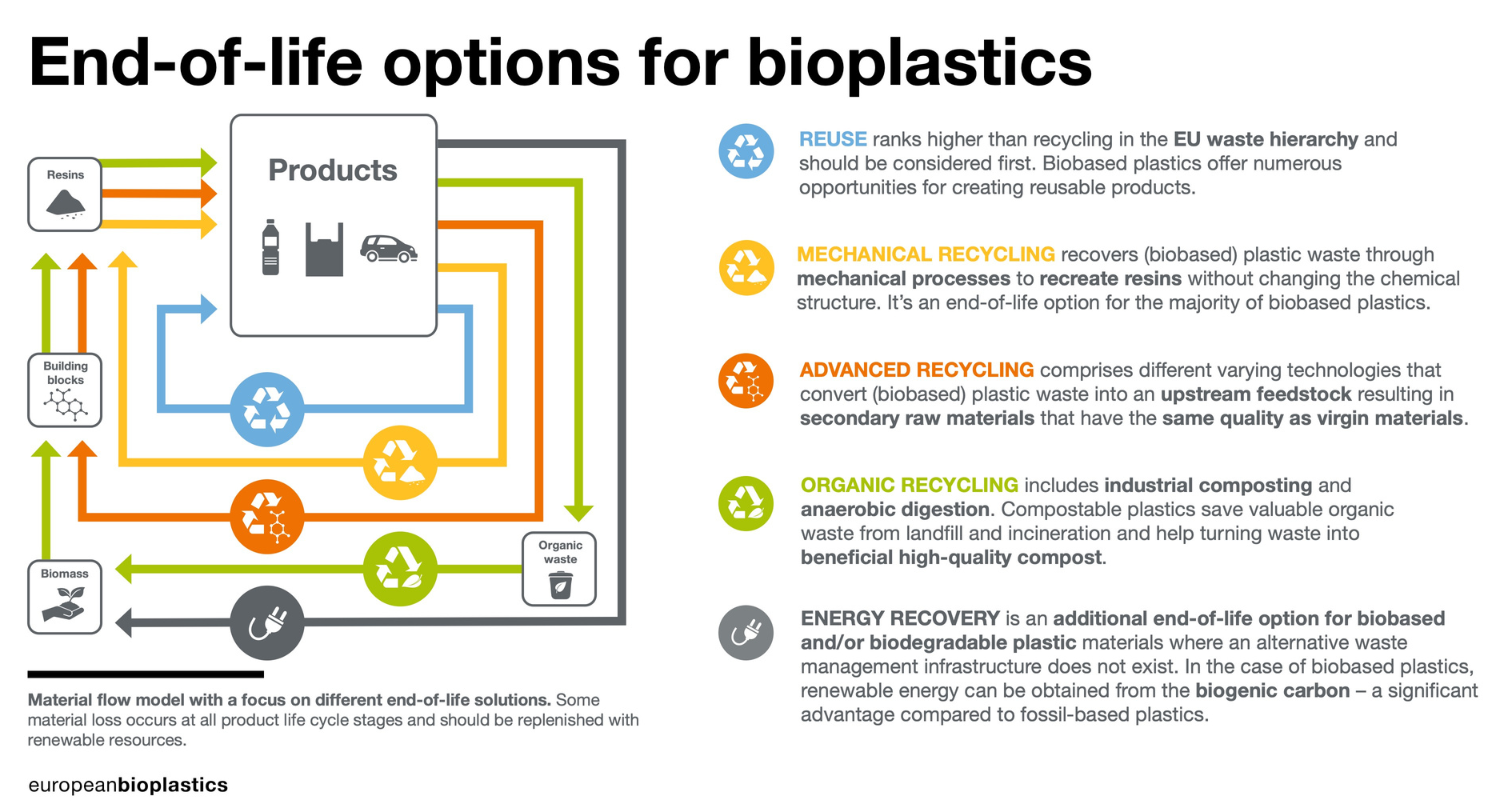

Biobased plastics have the unique advantage over conventional plastics to reduce the dependency on limited fossil resources and to reduce greenhouse gas emissions or even be carbon neutral. Consequently, biobased plastics can help the EU to meet its 2030 targets of greenhouse gas emissions reduction. Moreover, bioplastics can make a considerable contribution to increased resource efficiency through a closed resource cycle and use cascades, especially if biobased materials and products are being either reused or recycled and eventually used for energy recovery (i.e. renewable energy).

Climate protection

Utilising fossil resources in industrial processes increases the share of CO2 in the atmosphere, which causes an increase in the average temperature, the so-called greenhouse effect that is linked to the increasing prevalence of the number of thunderstorms, floods and aridity. Climate protection and the decrease of CO2 emissions is a central part of environmental policy around the globe due to the fact that climate change can create far-reaching negative consequences. Governments and organisations work against this threat with targeted measures.

In its Lead Markets Initiative, the EU Commission determined that bioplastics are of high importance due to their lower carbon impact. In 2023, the EU adopted a set of Commission proposals to make the EU’s climate, energy, transport and taxation policies fit for reducing net greenhouse gas emissions by at least 55% by 2030, compared to 1990 levels.

The increased use of renewable resources and an increased share of biobased products is an important step towards achieving these targets. Life cycle analyses show that biobased plastics enable a significant CO2 saving – up to carbon neutrality – compared to conventional plastics, depending on the feedstock, the product and the application.

A key tool to measure the environmental impact of products or services is the so-called Life Cycle Assessment (LCA). Through LCA it is possible to account for all the environmental impacts associated with a product or service. It covers all stages in a product’s life from the extraction of resources to ultimate disposal. LCA is the tool that allows measurement and reporting on current impacts, alternative scenarios and improvements achieved.

European Bioplastics supports LCA and Life Cycle Thinking (LCT) in order to promote, quantify, and substantiate the environmental sustainability of products. As emphasised above, it is crucial to take the complete product life cycle into account, as products may have entirely different environmental impacts during the single stages of their life cycle. LCT comprises the analysis of complete systems and avoids burden shifting from one life cycle stage to another, from one geographic area to another, and from one environmental medium to another.

A challenge for LCA is how to integrate untapped potential of innovative and rather “young” products, such as bioplastics, in a fair and comprehensive way. LCAs do not take into account the potential, which these materials and products have when they mature. Therefore, projections for improvements should be made and then included in LCA.