Spain announced plans to ban the sale of lightweight oxo-degradable bags from 2018 onwards under a new law drafted by the Spanish agriculture and environment ministry. The law implements an EU directive to reduce the consumption of lightweight plastic carrier bags. The draft also includes a minimum price on plastic bags above 15 microns and labelling requirements to aid the distinction of compostable bags from non-compostable bags.

Oxo-fragmentable plastics are conventional plastic materials with artificial additives that do not biodegrade but merely fragment into small pieces that remain in and potentially harm the environment and endanger recycling and composting.

Spain is the second country in Europe to take concrete actions to limit the harmful impacts of oxo-degradable plastics. In July 2015, France prohibited the production, distribution, sale, provision and utilization of packaging or bags made partially or completely of oxo-degradable plastics.

The European Commission is currently undertaking an assessment on the impact of oxo-degradable plastics on the environment. As set out in the amendment of the EU Directive on packaging and packaging waste from 2015 “a set of measures to limit their consumption or to reduce any harmful impacts” shall be proposed, if appropriate. The results will be presented in 2018, at the latest.

Constance Ißbrücker, Head of Environmental Affairs, EUBP

European Bioplastics has long been warning about the risks of oxo-degradable plastics and called out the increasing use of false and misleading labelling and greenwashing practices of some manufacturers of these materials. Constance Ißbrücker, Head of Environmental Affairs at European Bioplastics, explains the difference between biodegradable plastics and oxo-degradable plastics in an article in the current issue of the bioplasics MAGAZINE (Jan/Feb 2017):

Can additives make plastics biodegradable?

Biodegradability is an inherent property of a material or product resulting from the action of naturally occurring microorganisms, such as bacteria, fungi, and algae. The process produces water, carbon dioxide, and biomass. No additives are needed and no fragments remain in the environment. In the case of industrial composting, the requirements are clearly defined in internationally agreed standards such as EN13432, or ISO 18606. For biodegradation in other environments other standards can and should regulate the framework conditions and pass/fail criteria.

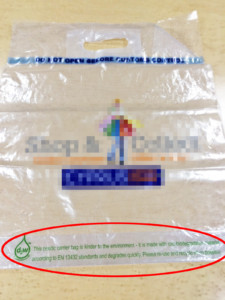

Misleading marketing claim: Shopping bag made from “oxo-degradable material” wrongly claims accordance to EN 13432. (Image taken in August 2015, © European Bioplastics)

So-called oxo-degradable plastics are commonly fossil-based, non-biodegradable polyolefins or polyesters (e.g. PE or PET) supplemented with salts of transition metals. These additives are supposed to enable the biodegradation of apparently non-biodegradable plastics. However, to date no reproducible study could provide satisfactory evidence for this, for example by measuring a significant amount of carbon dioxide evolvement, which is the standard indicator of and verification method for biodegradation. Publications in support of oxo-degradable plastics have claimed about 60% biodegradation in two years, leaving the fate of the remaining 40% up to speculation. Apart from the comparatively long time span (EN 13432 requires 90% disintegration in 12 weeks and biodegradation of 90% within six months), there are serious implications: It is assumed that oxo-degradable materials only disintegrate and finally visibly disappear under the influence of light (UV radiation) and oxygen. If no real biodegradation takes place simultaneously and subsequently, the process of disintegration results the formation of invisible plastic fragments, contributing to the ubiquitous environmental and health hazard of microplastics in the environment.

Another group of plastic materials supplemented with additives that are supposed to support biodegradation are so-called enzyme-mediated plastics. Naturally occurring biodegradation relies on enzymatic reactions initiated by naturally present organisms. The producers of enzyme-mediated plastics intend to emulate the process of biodegradation by adding enzymes to conventional polyolefins. So far no independent study or publication shows any positive results for such materials with regard to biodegradation, even though most of the producing companies are claiming that their plastics are 100% biodegradable or even compliant with accepted composting standards. These claims are often made not on the basis of conversion to carbon dioxide, but instead on the basis of mass loss, which is no scientific proof of biodegradation taking place.

It is important to clearly differentiate between different concepts in this context: Enzyme-mediated plastics should not be confused with recent promising research efforts focussing on a kind of enzymatic recycling. In the latter case waste of conventional plastics (e.g. PET or PU) waste are depolymerised through tailor-made enzymes. The obtained monomers can then function as raw material for the production of bioplastics such as PHA, which is biodegradable in numerous environments without the use of any supporting additives.

This article (Can additives make plastics biodegradable?) was first published in the bioplastics Magazine 01/2017.

Background information:

EUBP background paper on ‘oxo-degradable plasticst’

OWS report on ‘oxo-degradable plastics’

OWS report on ‘enzyme-mediated plastics’