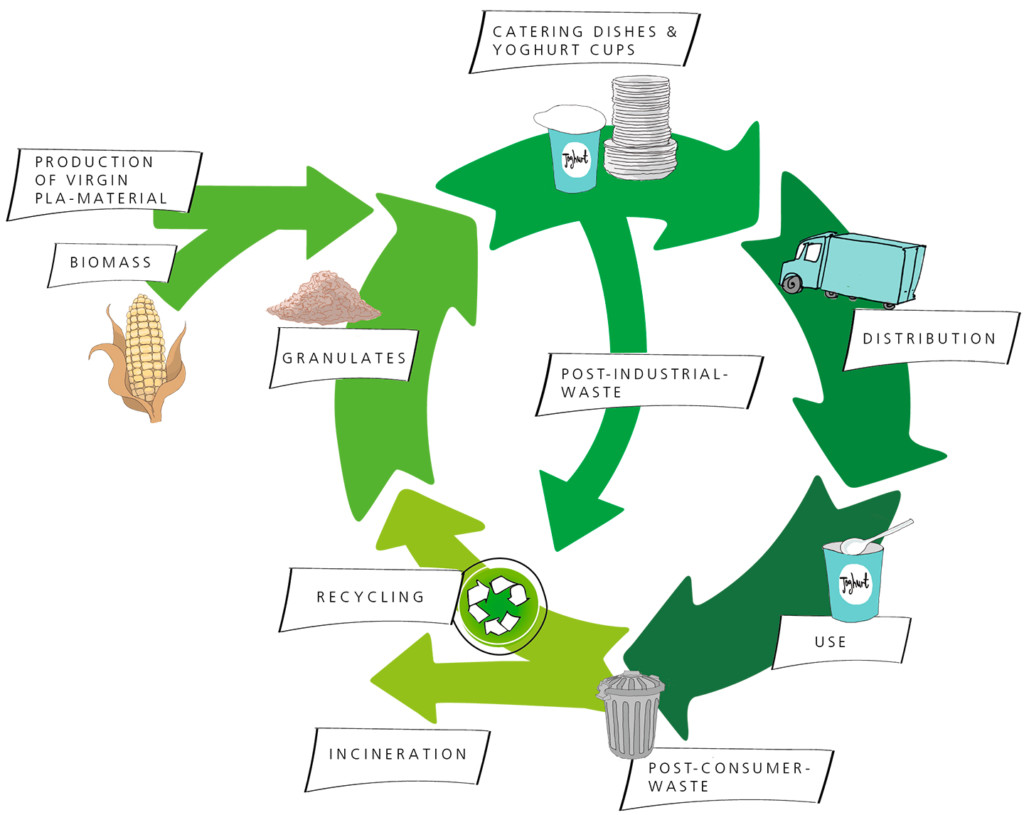

The new German packaging law (Verpackungsgesetz, effective from January 2019, we reported earlier this year) includes provisions under which the participation fees for packaging shall be adapted in order to incentivise the use of recycled and renewable materials. The consequential increase in bio-based plastic packaging and the expected rise of new types of materials entering the recycling streams led the German Ministry of Food and Agriculture (BMEL) to initiate a study on the disposal, sorting, and recycling of bio-based plastics, in particular of PLA, an innovative polymer that is 100 percent bio-based, very versatile, and especially suitable for packaging applications.

A research alliance* generated post-consumer as well as industrial waste containing PLA and tested the feasibility of material and feedstock recycling processes accompanied by life cycle assessments. The following findings are a summary of the results of these tests:

PLA in waste streams © Fraunhofer UMSICHT

Bio-based plastics are already being successfully recycled: bio-based drop-in plastics such as bio-based PET or bio-based PE have identical chemical structures to their conventional fossil-based counterparts and are already being recycled in high rates in existing recycling streams.

NIR identification and sorting of bio-based plastics from mixed post-consumer waste is possible: In the tests, PLA packaging was mixed with post-consumer lightweight packaging waste and was successfully separated using common near infrared (NIR) spectroscopy sorting technologies. With increasing volumes of PLA in post-consumer waste, establishing separate recycling streams will also become economically feasible.

Bio-based plastics do not interfere with the recycling of conventional fossil-based plastics: The tests have shown that up to 3 weight percent of PLA in post-consumer PP recyclates and up to 10 percent of PLA in PS re-granulates do not disturb or negatively effect the quality of the recycled material. The study also concludes that higher proportions of PLA would automatically encourage the establishment of separate PLA recycling streams as they would become economically feasible.

Recycling of bio-based plastics is environmentally beneficial: The life cycle assessment confirmed that mechanical recycling as well as feedstock recycling of PLA contributes to a reduction of environmental impacts due to the substitution of virgin material. Furthermore, recycling of PLA shows environmental benefits in almost all investigated impact categories compared to the application for energy recovery.

Products made from PLA meet market demands: The study could show that recycled PLA materials can be used in many sectors, including packaging, automotive, and gardening and agriculture.

Feedstock recycling of PLA is technically possible: The research alliance studied the integration of recycled PLA in the PLA synthesis process and could show that the generated material had the same quality as virgin material.

A summary of the study can be found here.

*The research alliance, supported by the BMEL, consists of eight partners, including Fraunhofer Institute for Manufacturing Engineering and Automation IPA, Fraunhofer Institute for Process Engineering and Packaging IVV, Fraunhofer Institute for Environmental, Safety, and Energy Technology UMSICHT, Fraunhofer Institute for Wood Research WKI, University of Applied Sciences Hannover, IfBB – Institute for Bioplastics and Biocomposites, Knoten Weimar, Technical University Chemnitz, and Bösel Plastic Management GmbH.