Exhibition

Why become an exhibitor?

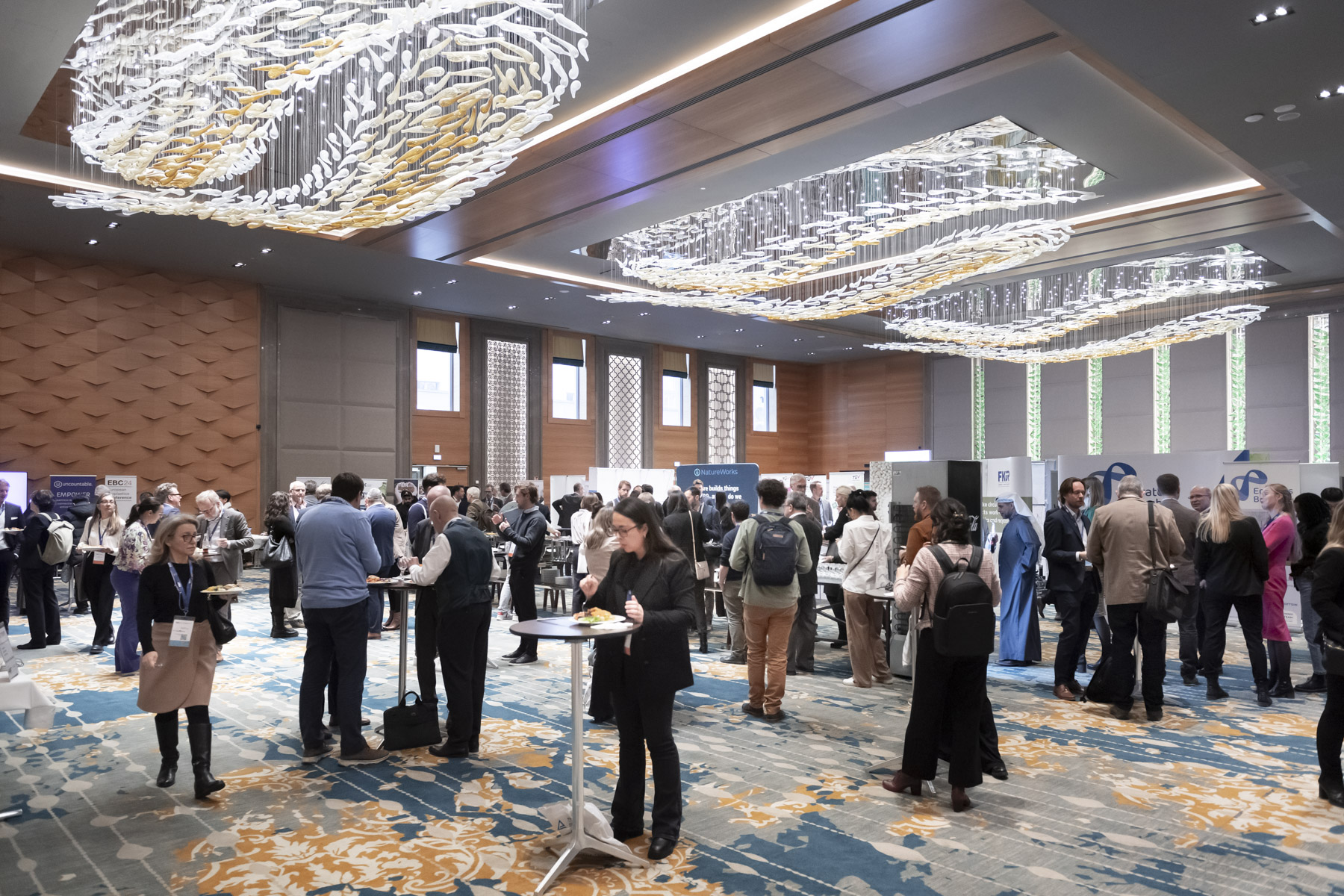

The exhibition is the ideal platform for your company to demonstrate your products and services, increase brand awareness, build new business relationships and gain instant market feedback. Like-minded delegates at the conference include visitors from the entire bioplastics value chain covering manufacturers, plastic converters, green chemistry, products, (industrial) end users, brand owners, research & consulting, as well as machinery & engineering.

How we promote you:

- You will have great visibility throughout the event thanks to your branded exhibition space, embedded in the catering and networking break area accompanying the conference.

- With plenty of networking breaks during the two-day event you can expect to have numerous one-on-one conversations.

- Being a hybrid event, you will also have your own space in our virtual exhibition hall, where you can provide documents and videos for our online attendees.

- We will feature your company logo and profile on conference materials handed out to all attendees on site, and in conference-related mailings.

- In addition, your company logo and profile will be up on the event website and linked up with your company’s online presence

| Exhibition options | Regular fee | EUBP member |

|---|---|---|

| Premium exhibition package incl. 1 delegate pass: Exhibition space measures 3.5m x 3.5m and you can bring your own individual stand equipment; electricity included |

2,800 €* | 2,600 €* |

| Standard exhibition package incl. 1 delegate pass: The classic tabletop option, including table, two chairs and space for 2 roll-ups; electricity included |

2,600 €* | 2,300 €* |

*Prices stated are excluding 19% VAT. Terms and conditions apply.